- Products

- Catalogs

- News & Trends

- Exhibitions

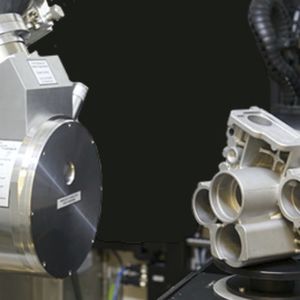

X-ray inspection machine XT H Seriescomputed tomographyindustrialfor the electronics industry

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, computed tomography

- Sector

- industrial, for the electronics industry, for the automotive industry, for the aerospace industry

- Other characteristics

- automated, measurement, high-resolution

- Convey weight capacity

15 kg, 50 kg

(33 lb, 110 lb)

Description

Nikon's adaptable microfocus CT systems provide high-resolution inspection of components, ranging from tiny plastic connectors to aluminium castings, for R&D, failure analysis and production quality control.

These systems combine the adaptability needed in the lab with unique features like 225 kV Rotating.Target 2.0, Half.Turn CT acquisition mode and Auto.Filament Control to shorten cycle time and improve uptime when used for shop floor series inspection.

Flexibility When You Need It

With the choice of source, targets, CT scanning strategies and options such as motorised source-to-detector distance adjustment, the XT H systems are versatile and accommodate a wide range of inspection tasks.

X.Tend Helical CT

Tall objects can be scanned in a single acquisition process, eliminating artifacts introduced by the cone beam and multi-scan stitching. This also provides the added benefit of scanning objects at higher magnification resulting in significantly higher resolution.

Unique 225 kV Rotating.Target 2.0

Allows continuous operation up to 450W with up to three times higher resolution for the same power, or three times faster data collection for a given resolution.

AI Reconstruction

Nikon's AI Reconstruction revolutionises computed tomography (CT) scanning through automated image enhancement powered by artificial intelligence (AI). Tailored to each customer's needs, it provides a new level of speed and quality to unlock superior defect detection while accelerating productivity.

VIDEO

Catalogs

Related Searches

- Laser scanning system

- Measurement scanning system

- 3D scanning system

- Inspection scanning system

- High-resolution scanning system

- High-precision scanning system

- High-speed scanning system

- Portable scanning system

- Fully integrated scanner

- Profile scanning system

- Hand-held scanner

- Quality control scanning system

- Non-contact scanner

- Surface inspection scanner

- Laboratory scanning system

- Cost-effective scanner

- Gap scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.