- Machine-tools

- Machining Center

- 5-axis machining center

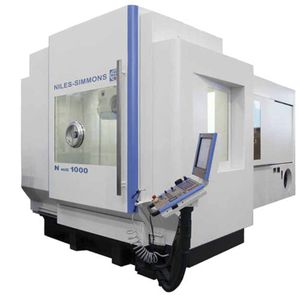

- Niles-Simmons Industrieanlagen

- Products

- Catalogs

- News & Trends

- Exhibitions

5-axis machining center NMILL 1900verticalgantryHSK F63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- gantry

- Spindle mount

- HSK F63, HSK-100

- Number of tool stations

- 120 tools

- Other characteristics

- high-precision

- X travel

1,880 mm

(74.02 in)- Y travel

1,400 mm

(55.12 in)- Z travel

720 mm, 910 mm

(28.35 in, 35.83 in)- Rotational speed

10,000 rpm, 15,000 rpm, 25,000 rpm

(62,832 rad.min-1, 94,248 rad.min-1, 157,080 rad.min-1)- Power

30 kW, 34 kW, 38 kW

(40.79 hp, 46.23 hp, 51.67 hp)- Work feed X-axis

40,000 mm/min

(26 in/s)- Work feed Y-axis

40,000 mm/min

(26 in/s)- Table load capacity

5,000 kg

(11,023 lb)

Description

Added value:

Gantry design for maximum robustness with heavy cast iron base and graduated high-precision guidance systems

Z‑Axis with milling spindle unit in a weightsaving robust sandwich construction

NC rotary table with a dynamic direct drive with hydraulic clamping at desired angle, rotary transmission for additional functions, optional speed range up to 250 rpm with automatic alignment function

Reliable high-precision spindles with oilair lubricant with HSK63 and HSK 100 interface, swivelling B‑Axis can be hydraulically clamped at desired angle

Model for turning that has an optional hydraulic clamping function for the spindle

Excellent ergonomics and accessibility

Uses the latest generation of control technology from HEIDENHAIN and SIEMENS

New, comfortable operating design with 19″ TFT monitors with NILES-HMI

Optional packages:

Triple pallet changer

Internal coolant supply, unregulated 40 bars of pressure | flow rate 2 5 l/min

Internal coolant supply, regulated 80 bars of pressure | flow rate 18 l/min

Rotoclear on front/side

Minimum lubrication

Coolant Mist extraction

Tool probing by using lasers

Tabletop load cell

Sensor for measuring workpiece

Higher precision

Thermal and vibration sensors

Remote diagnosis

Tailored solutions

Catalogs

Other Niles-Simmons Industrieanlagen products

5‑Axis- Machining Centres

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- 12 tools turning center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- 3-axis turning center

- Compact CNC machining center

- Vertical turning center

- Turning-milling machine

- CNC turning-milling center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.