- Machine-tools

- Machining Center

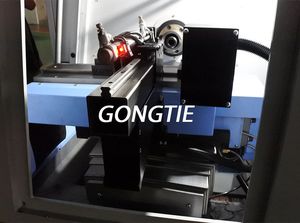

- CNC lathe

- Ningbo gongtie smart technology co., ltd.

CNC lathe Q serieshorizontal2-axisflatbed

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- horizontal

- Number of axes

- 2-axis

- Structure

- flatbed

- Applications

- for heavy-duty machining

- Performance

- high-precision, high-speed

- Options and accessories

- with integrated bar feeder

- Diameter

Min.: 98 mm

(3.86 in)Max.: 400 mm

(15.75 in)- Spindle speed

Min.: 0 rpm

(0 rad.min-1)Max.: 6,000 rpm

(37,699.112 rad.min-1)

Description

Q series-precise linear guide-way with flat bed in blade row : Q5,Q7,Q5C,Q7C

Q5 ,Q7, with the features of high precision. high speed. high efficiency, is the ideal selection for substituting hard rail lathes and imported lathes.

* High precision: importing components from Japan and Taiwan through the advanced assembly and inspection technology, realizing the precise turning with tolerance of μ level.

* High speed: more than 5000RPM for spindle ,rapid traverse 20m/s, to reach the high speed machining.

*High-efficiency:with the concept of technique innovation and application oriented, and sustainability improve the overall performance, to make the processing more efficiency.

* Stability: high quality requirement and strict selecting for all the components, to make the machine performance more stable.

Q5C,Q7C, (Synchronous electric spindle)- the best selection for substituting the imported lathes.

* More precision: the complete Synchronous servo configuration for the spindle and the X/Z axis, makes the processing accuracy get a new break through.

* Higher speed: the superior Synchronous electric spindle make the spindle perform higher, faster, and more stable.

* More efficiency: the complete, Synchronous control for the core parts (all the axis),makes the processing efficiency better.

For this technical solution,we use one vibration pan to combine the precise Q series CNC lathe to realize the processing of paratypic and small shafts or pan - type work pieces.

Catalogs

products catalogue

12 Pages

Other Ningbo gongtie smart technology co., ltd. products

CNC+Simple Feeding System

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- High-rigidity CNC machining center

- Milling CNC machining center

- Column type CNC machining center

- High-rigidity turning center

- High-performance turning center

- 3-axis turning center

- Compact CNC machining center

- Vertical turning center

- High-productivity turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.