- Industrial machines and equipment

- Welding and Assembly

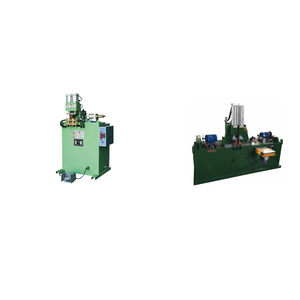

- Butt welding machine

- Ningbo Xinchang Machinery Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Butt welding machine UN-1000 PLC-controlledhydraulic

Add to favorites

Compare this product

Characteristics

- Technique

- butt

- Operational mode

- PLC-controlled

- Other characteristics

- hydraulic

Description

This machine consists of body, right, left, up and down, static and dynamic arm(all the parts casted by cast steel), electrode clamp, transverse driven upsetting device, hydraulic system, electric control system and welding transformer system..

1.Taking advantages of good idea from Hess Corp, USA, we equip hydraulic system to control clamp, melted, upset and adjustment of melting which keep the accuracy of different melting series. The clamp is made of high conductive hard chrome zirconium copper, wear resisting, and easy to clean.

2.Main transformer

The transformer is casted by two sides nonmagnetic aluminum head epoxy resin and made of imported high quality conductive magnetic steel sheet and electromagnetic wire. There are many advantages such as vacuum impregnation, temperature resistance, anti-seismic, high insulation ratio, small detectable leakage, energy conservation, high conductivity and high output power. This machine, built in temperature sensor, is straight shell type structure with secondary cooling the copper plate in the middle of copper pipe. It has characteristics of compact structure, fast cooling and low energy consumption with high efficiency and all the components are imported parts(Omron/PLC, inverter, press button and relay pilot light, etc).

3.This machine is controlled by LIYANGPLC, Taiwan which have both manual and automatic program to ensure the reliability of the device. In automatic state, if we meet emergency, the welding process should be terminated forcibly, then after handling properly, reset the program and going on welding.

Other Ningbo Xinchang Machinery Co., Ltd. products

Butt welding machine

Related Searches

- Welding system

- Automatic welding system

- Arc welding system

- Precision welding system

- Resistance welding system

- Compact welding system

- Butt welding machine

- CNC welding system

- PLC-controlled welding system

- Pneumatic welding system

- Semi-automatic welding system

- Electric welding system

- Hydraulic welding machine

- Spot welding system

- Water-cooled welding machine

- Three-phase welding system

- Custom welding system

- Rotary welding system

- Seam welding system

- Longitudinal welding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.