- Electricity - Electronics

- Cable, Connector, Enclosure

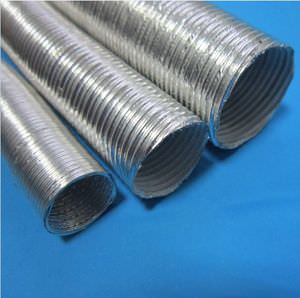

- Thermal protection sleeve

- Ningguo BST Thermal Products Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Carbon fiber sleeve K seriesthermal protectionbraidedexhaust pipe

Add to favorites

Compare this product

Characteristics

- Type

- thermal protection

- Structure

- braided

- Applications

- exhaust pipe

- Material

- carbon fiber

- Color

- black

- Other characteristics

- flexible

- Diameter

Max.: 127 mm

(5 in)Min.: 8 mm

(0.3 in)

Description

The Carbon Fiber Braided Sleeve is designed to create strong and aesthetically pleasing tubes and sections. It works by sliding over a mandrel or a release coated tube. It can accommodate a wide-range of diameters through sleeve expansion up to 30% and contraction up to 70% of the given diameter. Braided sleeves are known for their superior resistance to cracks between layers and they reduce the risk of delamination, while strengthening the product.

An inflated braided reinforcement performs like the body of a shark, positioning itself in the direction of the force. The outer skin is strengthened and gives it the capacity to withstand pressure, tolerate damage, take fatigue, and carry loads. In case of a puncture, the sleeve controls the progression of damage, averting the risk of a dangerous blowup.

The Carbon Fiber consists of very thin fibers and is denser than steel, making it perfect for use with applications needing low weight. It is light but stable and rigid, corrosion free, offers thermal stability, electrical conductivity, electromagnetic protection, and great wear resistance, leading to a long life.

Catalogs

No catalogs are available for this product.

See all of Ningguo BST Thermal Products Co.,Ltd‘s catalogsOther Ningguo BST Thermal Products Co.,Ltd products

Heat Protection Tube

Related Searches

- Adhesive tape

- Cable conduit

- Protection conduit

- Plastic conduit

- Flexible conduit

- Tubular conduit

- Band clamp

- Electrical cable conduit

- Braided conduit

- Fire-resistant conduit

- Wire sleeve

- Black conduit

- Stainless steel band clamp

- Heat-shrinkable conduit

- Corrugated conduit

- Pipe conduit

- Insulating adhesive tape

- Insulating conduit

- Worm-drive hose clamp

- Abrasion-resistant conduit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.