- Products

- Diaphragm pump

- Nitto Kohki Europe

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

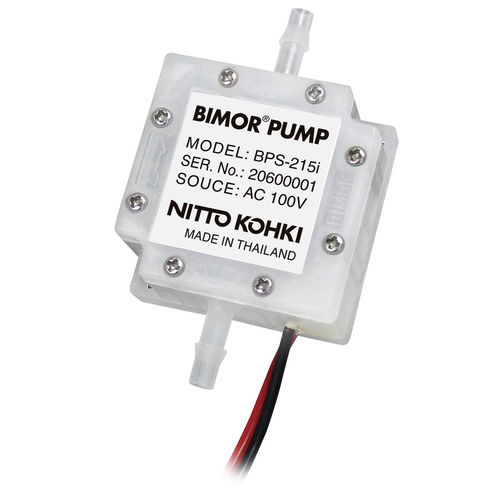

Piezoelectric pump BIMOR BPS 120V seriesdiaphragmfor chemicalsself-priming

Add to favorites

Compare this product

Characteristics

- Technology

- diaphragm

- Fluid

- for chemicals

- Operation

- piezoelectric

- Priming

- self-priming

- Mobility

- stationary

- Domain

- for the chemical industry

- Material

- PP, PTFE

- Voltage

- 120 V

- Other characteristics

- compact, small

- Flow

0.003 l/min

(0.00079 us gal/min)- Pressure

150 mbar

(2.176 psi)- Weight

40 g

(1.41 oz)

Description

Operating principle

The Bimor's driving force, the bimorph, comprises two parallel piezoelectric wafers. Their nature is to expand or contract depending on the direction of the voltage. Therefore, when an alternating current is applied, one wafer expands then contracts while the other contracts then expands, causing the biomorph to bend. Repeating the cycle creates a pumping action, as the diagram below shows.

Specifications

Current: - 3 mA

Flow Rate: - 30 ml/min

Outlet Pressure: - 150 mbar

Self-Priming Pressure: - 30 mbar

Housing Material: - PP

Bimorph Material: - PP

Valve / O-Ring: - IIR

Weight: - 40 g

Suitable Liquids: - Chlorinated Detergents

Compact, lightweight, durable & quiet

As the Bimorph also acts as a diaphragm it has no motors or shafts or other troublesome mechanisms, and thus

minimal vibrations and fewer breakdowns. The Bimor is lighter, quieter and more durable than traditional pumps.

We have achieved maintenance free continuous operation for 60 months.

Low power consumption & electromagnetic noise

The Bimor is driven by low energy consuming piezoelectric elements.

Consequently it costs very little to run and emits virtually no electromagnetic noise.

Simple flow rate adjustment

As the flow rate of the Bimor is proportional to the voltage and frequency, adjusting the flow rate is as simple

as adjusting either one.

You may use the product at the rated voltage or lower.

Application versatility

The parts can be made of several different materials, so you can select the material appropriate to your needs, be it

a liquid application.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Nitto Kohki Europe‘s catalogsOther Nitto Kohki Europe products

BIMOR Piezoelectric 120 V / 60 Hz

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.