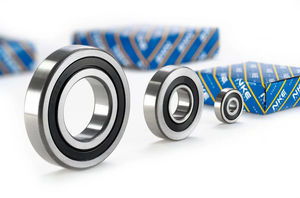

Ball bearing bearing radialsteelfor industry

Add to favorites

Compare this product

Characteristics

- Rolling element

- ball bearing

- Configuration

- radial

- Material

- steel

- Applications

- for industry

- Other characteristics

- high-speed, low-friction, corrosion-resistant, high-rigidity, hybrid, wear-resistant, electrically isolated

Description

Tough industrial applications require special bearings.

NKE hybrid bearings are consist of steel rings and bearing silicon nitride Si3N4 rolling elements.

Advantages for the user of NKE HYBRID Bearings

-Insulation: highest protection against passage of electric

-Higher speed suitability: centrifugal force reduction due to the light rolling elements

-Lightweight: Silicon nitride is 60% lighter than conventional rolling element steel

-Extended service life: longer bearing life and longer re-lubrication intervals

-Reduced friction: less frictional heat, especially at high speeds

-High wear resistance

-Higher rigidity: less deformation in rolling contact areas

-Reduced risk of poor lubrication at high speeds and fast accelerations, or in the case of insufficient lubricating film

-Low running noise operational bearings

-Significantly less susceptible to standstill marks known as “false brinelling”

-Reduced thermal expansion

-More precise control of preload and bearing clearance

-Dimensionally interchangeable

-No additional tools required

Properties of ceramic rolling elements

-Electrically isolating

-Low friction coefficient

-Corrosion resistant

-Higher modulus of elasticity

VIDEO

Catalogs

No catalogs are available for this product.

See all of NKE AUSTRIA GmbH‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Single-row bearing

- Bearing unit

- Deep groove ball bearing

- Double-row bearing

- Cylindrical roller rolling bearing

- Cage assembly bearing

- Tapered roller bearing

- Metal bearing unit

- Angular-contact bearing

- High-speed bearing

- Industry bearing

- Axis cam follower

- Sealed bearing

- Machine bearing

- High-performance bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.