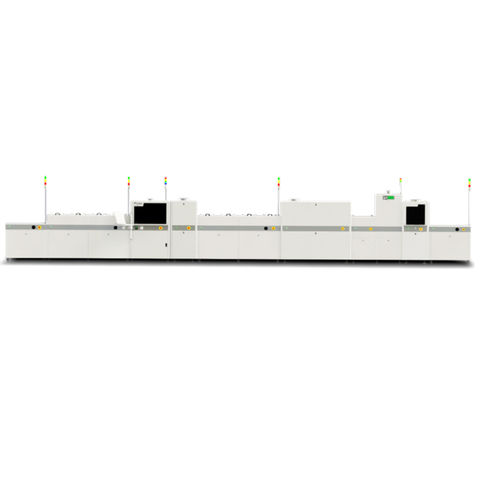

Automatic liner production line Panorama series

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

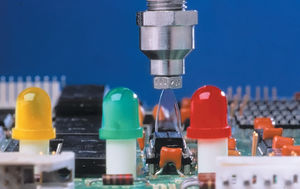

Nordson ASYMTEK designs automated conformal coating line solutions to fit your production process. Every Panorama™ line we build, includes the right balance of equipment and process control for optimal coating efficiency.

If you’re transitioning to automation or replacing depreciated or outdated equipment, our skilled technicians can design a creative coating line solution to meet your specifications.

A Coating Line for Every Process

Because our lines are modular, configuration possibilities are highly flexible and it’s easy to add equipment as needed. With a Nordson ASYMTEK line solution, you can rely on our team as your single point of contact for support and maintenance needs, process improvements, and smart solutions. Process control and automation work together to create efficiency across every Nordson ASYMTEK coating line.

Every line solution delivers:

• A full range of equipment options

• Minimal operator interaction

• Closed-loop controls, parameter limits and inspection across the line

• Process data for improved productivity

• Stability and consistency at every step

The Panorama C-Line takes conformal coating to the next-level with advanced process control. Each component fits seamlessly together to deliver powerful coating and curing capabilities, closed-loop controls, and data to fuel continuous process improvement

The Panorama S-Line delivers conformal coating process control in a compact footprint – with overlapping line processes that minimize manufacturing floor space use up to 50%. In this revolutionary patent-pending line layout, the lower compartment in each piece of equipment can include a curing or flash-off process.

VIDEO

Catalogs

Panorama™ C-Line

12 Pages

ASYMTEK Panorama S-Line

14 Pages

Other Nordson ASYMTEK products

Conformal coating equipment and accessories

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.