- Industrial machines and equipment

- Surface Treatment Equipment

- Enclosed powder coating booth

- Nordson Industrial Coating Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

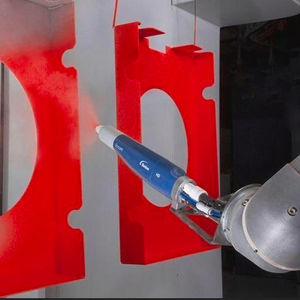

Enclosed powder coating booth ColorMax®2cycloneautomatic

Add to favorites

Compare this product

Characteristics

- Structure

- enclosed

- Filter type

- cyclone

- Other characteristics

- automatic

Description

Nordson automatic powder coating booths enable our customers to achieve more productivity and powder and energy savings.

Flexible powder coating without compromise

With a powder coating spray booth range that features automated applications and choices of batch, cartridge or cyclone booth systems, Nordson improve your productivity of your powder coating line and provide flexibility to enable your production requirements. Whether it's single-color mass production or fast, contamination-free color changes for batch size 1 powder coating, Venturi-pump or HDLV-pump technology, and enamel coating, organic or metallic powder, we have the right solution for you.

Down with costs, up with quality!

From countless variants, selecting just one: That’s what consumers today prize most when purchasing many of the articles of everyday life. For powder coating equipment operations, this trend places high demands on flexibility and productivity if they want to manufacture products profitably even in “Batch size 1”.

The ColorMax®2 quick color change powder spray system is optimized for efficient, repeatable powder application. Numerous features minimize powder in process and aid in system cleaning – providing you with fast, contamination-free color change.

Available in three model types – engineered, cubed and hybrid to meet varying application needs.

Optimized powder recovery/recycling

Pre-assembled utility deck speeds installation time

AeroWash™ Base Cleaning System and AeroDeck™ Air Distribution System ensure minimal powder build up

The Encore Engage Control System provides closed-loop digital control of atomizing and flow rate

Catalogs

Other Nordson Industrial Coating Systems products

Coating

Related Searches

- Automatic washing machine

- Process washing machine

- Spray gun

- Spray washing machine

- Paint gun

- Automatic gun

- Dosing gun

- Glue gun

- Lightweight gun

- Surface treatment gun

- Compact gun

- Powder coating booth

- Powder coating machine

- Coating application system

- Manual powder coating machine

- Automatic powder coating booth

- Airless gun

- Electrostatic gun

- Powder coating gun

- Manual powder coating booth

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.