- Industrial machines and equipment

- Welding and Assembly

- UV curing system

- Nordson Industrial Coating Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

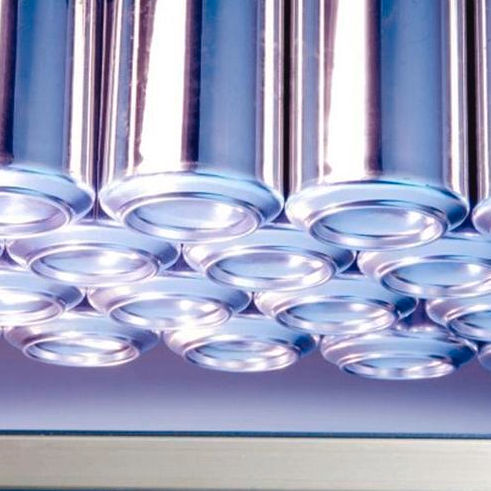

UV curing system CoolWave® 2

Add to favorites

Compare this product

Characteristics

- Options

- UV

Description

Fast, efficient UV curing system for wear resistant, zero VOC bottom rim coating to improve mobility and guard against can jams, for greater throughput.

Improve mobility and guard against can jams, for greater throughput

Can makers apply a rim coating to the bottom rim of two-piece D&I cans to greatly increase the mobility of the cans during production. This results in fewer can jams and significantly increased productivity. Rim cure coating is typically applied immediately to all the cans as they exit the washer, and are transported on a wide vacuum conveyor belt, with can bottoms down.

The cans are then conveyed over a single wide roller, where the rim coating is applied as the cans move directly over the UV curing station. Designed for two-piece can manufacturing, the Nordson CoolWave® 2 UV Rim Cure System features the most advanced and reliable microwave-powered UV systems on the market today.

Every power supply features:

Remote I/O as a standard feature

Electrical noise filtration

Simple operator interface

CE approvals

Clean efficient design for reduced costly downtime

Digital display for ease of troubleshooting

Features and Advantages

No Internal Gasketing - The design has eliminated the maintenance intensive internal gasketing in the microwave cavity. This reduces your operational and maintenance costs, as well as expensive downtime related to internal arcing.

Cooler Operation – The dichroic-coated reflector does not reflect all of the heat-generating infrared light waves back to the substrate. The result is precisely focused UV light where you need it without the damaging

Catalogs

CoolWave® 2

2 Pages

Other Nordson Industrial Coating Systems products

Treating& Curing

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.