- Industrial machines and equipment

- Surface Treatment Equipment

- Spraying gun

- Nordson Industrial Coating Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

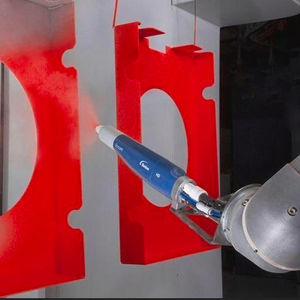

Spray gun A7Apaintautomaticairless

Add to favorites

Compare this product

Characteristics

- Function

- spray

- Product

- paint

- Operational mode

- automatic

- Other characteristics

- airless

- Pressure

1,700 psi, 3,000 psi

Description

Nordson automatic airless A7A system, with A7A guns, produce fine atomization and a soft, controllable spray to deliver excellent finish quality with minimal overspray.

Whether you are dealing with dozens or thousands of steel drums, Nordson has systems that provide a variety of benefits to your high-speed manufacturing and reconditioning lines.

Air-actuated A7A guns provide fast response time (30 to 40 milliseconds) and high-speed cycling capability (up to 2500 cycles per minute), and are ideal for coating situations requiring precise material application.

A7A Spray System

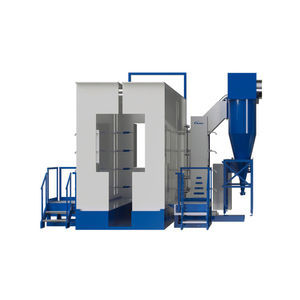

Nordson offers a complete line of airless spray systems specifically for drum manufacturers and reconditioners. Our systems include proprietary spray nozzles, spray guns, nozzles, heaters, filters and more. All are designed to deliver consistent quality and reliable performance, helping you achieve today’s demanding production requirements.

Features and Benefits

Nordson A7A automatic airless spray guns are designed to deliver maximum reliability in high-production airless painting applications.

Fast cycling with positive cutoff – provides precise operation with minimal dripping and spitting.

Rugged, production-proven construction – minimizes downtime and maintenance costs.

Several models available – dual-chamber guns can be used on drum painting lines to provide fast cleaning/ color change with no downtime. Stainless steel models apply waterbornes and highly corrosive materials, or can be used in special food or drug applications.

Compact, rugged construction – ensures long life and low maintenance costs.

Catalogs

Other Nordson Industrial Coating Systems products

Coating

Related Searches

- Automatic washing machine

- Process washing machine

- Spray gun

- Spray washing machine

- Paint gun

- Automatic gun

- Dosing gun

- Glue gun

- Lightweight gun

- Surface treatment gun

- Compact gun

- Powder coating booth

- Powder coating machine

- Coating application system

- Manual powder coating machine

- Automatic powder coating booth

- Airless gun

- Electrostatic gun

- Powder coating gun

- Manual powder coating booth

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.