- Metrology - Laboratory

- Metrology and Test Equipment

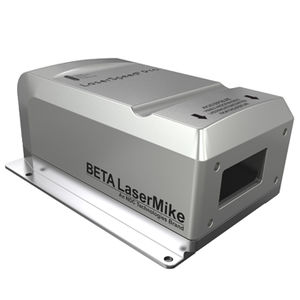

- Diameter measuring instrument

- Nordson Measurement & Control

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Diameter gauge AccuScan 6000 serieseccentricityscanningprocess

Add to favorites

Compare this product

Characteristics

- Measured value

- eccentricity, diameter

- Technology

- scanning

- Applications

- for pipe, for cables, process

- Other characteristics

- high-precision, ultra-rapid, 4-axis

Description

Ultra-Accurate, Four-Axis Diameter and Ovality Gauges

The industry's only four-axis scanning diameter & ovality gauge, providing the highest accuracy to ensure your products meet the tightest design and quality specifications.

• Most Comprehensive Measurement Coverage – provides more accurate average diameter on products up to 50 mm

• Highest Ovality Accuracy – up to 100%, unlike three-axis gauges

• Highest Flaw Detection Accuracy – 25% improvement over three axis-gauges

• Highest Product Quality Yield – offers significant manufacturing savings

• Ultra-Fast Measurements – up to 9600 scans per second

• Preeminent Support – all systems are backed by NDC's dedicated worldwide customer service organization available 24-7 via myNDC cloud service

Product Details

Get Ready to Experience Unmatched Performance and Numerous Quality and Production Advantages

The AccuScan 6000 Series gauge provides the most comprehensive measurement coverage around your product's circumference to instantly detect changes in product diameter and ovality. This ultra-accurate gauge suitable for a wide range of applications such as pipe and tube, wire and cable, and other extruded or drawn cylindrical or shaped products. Two gauges are offered:

• AccuScan 6012 -- measures products up to 12 mm

• AccuScan 6050 -- measures products up to 50 mm

The AccuScan 6000 Series gauge offers flexible communications for easy integration into your product environment and can be combined with our InControl process controller along with other Beta LaserMike dimensional monitoring gauges for a complete process quality control solution.

Other Nordson Measurement & Control products

Cable, Tube & Other Industries

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Thickness measuring machine

- Automatic test equipment

- Micrometer

- Optical measuring machine

- Industrial gauge

- Laser scanning system

- Moisture meter

- Measurement scanning system

- Industrial test equipment

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Compact measuring device

- Coating thickness gauge

- Control measuring machine

- Non-contact measuring machine

- Laboratory measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.