- Metrology - Laboratory

- Metrology and Test Equipment

- Diameter measuring instrument

- Nordson Measurement & Control

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

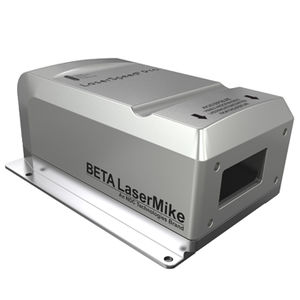

Diameter gauge CenterScan 2010eccentricitynon-contactfor cables

Add to favorites

Compare this product

Characteristics

- Measured value

- eccentricity, diameter

- Technology

- non-contact

- Applications

- for pipe, for cables, cable sheath and core insulation

- Configuration

- compact

- Other characteristics

- high-precision

Description

Non-Contact Eccentricity Measurement system

Accurately, reliably measure the insulation diameter and conductor eccentricity of your wire and cable to maximize product quality and reduce production scrap.

• High-Performance Gauging – perform non-contact measurements at higher line speeds to produce more finished product in less time while maintaining the highest level of accuracy

• Fast, Easy Setup and Operation – factory calibrated and requires no special adjustments or setups to get your cable properly centered and ready to run

• Versatile Installation – compact design enables you to install the gauge at a wider range of production line locations

• Flexible Communications – supports a wide range of communication protocols for easy integration into processes

• Friendly Control – easily access, view and configure gauge functions via optional ultra-bright display

Capture Non-Contact Eccentricity Measurements and More with the Highest Accuracy

CenterScan 2010 is the most versatile gauge of its kind, allowing you to perform eccentricity, diameter and flaw detection measurements in one gauge head. It can measure diameters from 0.1 - 10 mm with +/-0.0005 mm accuracy and with 0.00001 mm resolution at gauging speeds up to 1200 measurements per axis per second.

CenterScan 2010 can also be combined with our InControl process controller along with other Beta LaserMike dimensional monitoring gauges for a complete process quality control solution.

Other Nordson Measurement & Control products

Cable, Tube & Other Industries

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Thickness measuring machine

- Automatic test equipment

- Micrometer

- Optical measuring machine

- Industrial gauge

- Laser scanning system

- Moisture meter

- Measurement scanning system

- Industrial test equipment

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Compact measuring device

- Coating thickness gauge

- Control measuring machine

- Non-contact measuring machine

- Laboratory measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.