- Metrology - Laboratory

- Metrology and Test Equipment

- Cable flaw detector

- Nordson Measurement & Control

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

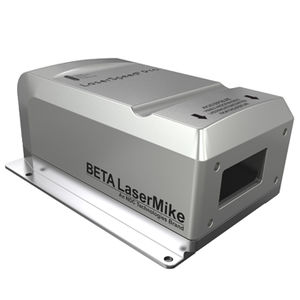

Cable flaw detector LN3000 seriesfixeddigital

Add to favorites

Compare this product

Characteristics

- Applications

- for cables

- Portability

- fixed

- Options and accessories

- digital

Description

Highest Accuracy Three-Axis Detect Lump and Neckdown Detectors

Quickly, reliably detect and locate product flaws, such as lump and neckdowns, before they become costly production problems to ensure maximum quality control.

• Ultra-Fast Flaw Detection – three-axis gauging coupled with fast response circuitry rapidly detects flaw heights down to 0.02 mm at line speeds up to 3000 m/min.

• Continuous Quality Control – effectively monitor and report on critical flaw data and gauge performance to produce the highest quality products

• Flexible Communications – supports a wide range of communication protocols for easy integration into processes

• Lowest TCO – sealed, rugged design minimizes light and dust contamination and provides long, reliable service life

• Preeminent Support – all systems are backed by NDC's dedicated worldwide customer service organization available 24-7 via myNDC cloud service

Product Details

High-Precision, Three-Axis Flaw Detection for Continuous Quality Manufacturing

The LN3000 Series 3-axis gauge provides precise detection of short-term faults in the product diameter at higher line speeds than two-axis systems. Two models are available:

• LN3015 for products up to 15 mm in diameter

• LN3040 for products up to 40 mm in diameter

The LN3015 offers ±0.011 mm accuracy, while the LN3040 offers ±0.018 mm accuracy (or ±3% max flaw height).

Both gauges can be easily connected to a host PC or PLC using RS232, Telnet, EtherNet/IP, Ethernet, DeviceNet, Profibus and Profinet.

Catalogs

No catalogs are available for this product.

See all of Nordson Measurement & Control‘s catalogsOther Nordson Measurement & Control products

Cable, Tube & Other Industries

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Thickness measuring machine

- Automatic test equipment

- Micrometer

- Optical measuring machine

- Industrial gauge

- Laser scanning system

- Measurement scanning system

- Moisture meter

- Industrial test equipment

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Compact measuring device

- Coating thickness gauge

- Control measuring machine

- Non-contact measuring machine

- High-precision measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.