- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Electric preheater

- Nordson Measurement & Control

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Wire preheater electric

Add to favorites

Compare this product

Characteristics

- Heating method

- electric

- Applications

- for wire

Description

High-Performance, In-Process Wire Heating

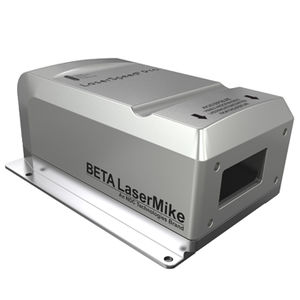

BETA LaserMike Preheaters provide uniform, in-process wire heating to eliminate insulation voids in primary cables.

• Improve Performance and Quality – high-frequency heating ensures faster extrusion speed and desired adhesion, elongation, and foam rate; and minimizes micro-cracks in extruded material

• Maximize Production Uptime – highly reliable preheater components ensure that power losses are minimized and that all input power is used to heat the wire with a 94% efficiency rate

• Protect Personnel and Equipment – proven safety features including wire break detection, current overload sensors, and a wire path that is concealed behind an electrically locked door

• Better Control Heating – preheaters are equipped with the new TempTrac Pro™ non-contact temperature measurement system for high-accuracy monitoring and control of preheat temperatures

Performance Built for Your Wire Preheating Applications

• Industry Leading Safety Features – protect personnel and equipment with wire break detection, current overload sensors and a concealed wire path behind the electrically locked door

• Maximum Operational Flexibility – with external temperature controller interface that compensates for low-speed applications and varying input temperatures

• Efficient Power Control – all preheater components are carefully designed to ensure that power losses are minimized and all input power is used to heat the wire

• Wide Product Coverage – preheat products from 0.28 – 2.8 mm OD at line speeds up to 2500 m/min

Catalogs

No catalogs are available for this product.

See all of Nordson Measurement & Control‘s catalogsOther Nordson Measurement & Control products

Cable, Tube & Other Industries

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.