- Metrology - Laboratory

- Metrology and Test Equipment

- Speed measuring instrument

- Nordson Measurement & Control

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

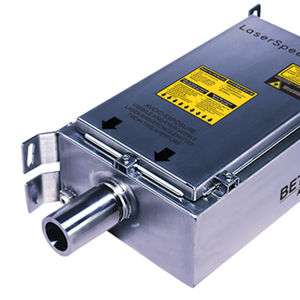

Length measuring instrument LaserSpeed Pro seriesspeednon-contactlaser

Add to favorites

Compare this product

Characteristics

- Measured value

- length, speed

- Technology

- non-contact, laser

- Applications

- industrial, for metallurgical applications, for sheet metal

- Other characteristics

- high-precision, continuous

Description

The LaserSpeed® Pro gauge replaces your error-prone contact encoders with laser precision measurements to begin realizing immediate production savings. The LaserSpeed Pro 8500 gauge can be used to measure the absolute length and speed in any continuous or discrete length gauging process. The LaserSpeed Pro 9500 measures forward and reverse directions, and down to “true” zero speed on all types of metal products.

• Most Installed Gauge – 25-plus years in service in over 8,000 installations worldwide

• Highest Industry Accuracy – non-contact method with better than +/-0.03% accuracy, +/-0.02% repeatability improves process control, product quality, and bottom-line

• Versatile Measurements – steel slabs, cold steel strip, bar length, plate length, pipe/tube length, process lines, painting lines, galvanizing lines and more

• Supports Industry 4.0 – most versatile Ethernet connectivity, communication and control capabilities for easy integration into production networks

• Lowest TCO – factory calibration and no moving parts to wear out reduces maintenance, saves time and money

• Preeminent Support – all systems are backed by NDC's dedicated worldwide customer service organization available 24-7 via myNDC cloud service

LaserSpeed Pro is a Proven Performer in All Types of Mill Applications

The LaserSpeed non-contact length & speed gauge has long been the preferred measurement solution for quality-conscious manufacturers everywhere. It is proven in numerous mill applications involving:

• Continuous slab casters

• Billet and bloom casters

• Cutting control

• Elongation control in temper and skin pass mills

• Gauge control in cold rolling mills

• And more…

Catalogs

No catalogs are available for this product.

See all of Nordson Measurement & Control‘s catalogsOther Nordson Measurement & Control products

Metals Processing

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Thickness measuring machine

- Automatic test equipment

- Micrometer

- Optical measuring machine

- Industrial gauge

- Laser scanning system

- Measurement scanning system

- Moisture meter

- Industrial test equipment

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Compact measuring device

- Coating thickness gauge

- Control measuring machine

- Non-contact measuring machine

- High-precision measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.