- Production Machines

- Plastics Processing

- Extrusion die

- Nordson Polymer Processing Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

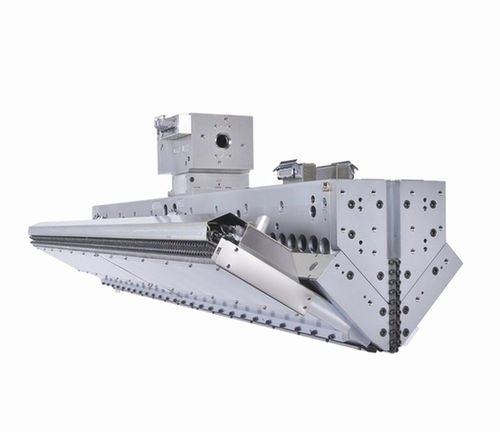

Extrusion die EDI® BOPET

Add to favorites

Compare this product

Description

With the most BOPET installations in the world, Nordson offers processors a field-proven solution delivered by experienced and knowledgeable experts.

Overview

Processors have long tried to solve the problem of ensuring their film is produced with consistent strength and durability, while also meeting the visual requirement dictated by the end product's use. To do this, the structural elements in the film must be proportionally extruded across its width.

Delivering Uniform Film Structures

The uniform and precise layer-to-layer structure created by an EDI® die system means the film's integrity remains intact during stretching, creating an end product with exceptional protective qualities against chemical and environmental factors.

Coextrusion Capabilities - Possible with either a multi-manifold die or a single manifold die and feedblock

Manifold - Multiflow™ I or II coathanger-shaped manifold

Gauge Control - Autoflex™ automatic or manual lip adjustment systems available

Designed to Suit Your Process

Finishing Options - Surfaces are finished to a mirror-like appearance, delivering exceptional end product quality

Production Line Integration - Adaptable to interface with new or existing production lines

Additional Features - Production runs can be extended by adding tungsten carbide coating or laser-hardening to die lips; angled lip exits are also available

Catalogs

No catalogs are available for this product.

See all of Nordson Polymer Processing Systems‘s catalogsOther Nordson Polymer Processing Systems products

EXTRUSION

Related Searches

- Drying system

- Pelletizer

- Plastic pelletizer

- Vacuum drying system

- Compact pelletizer

- Plastic dewatering system

- Plastic pellet dryer

- Melt pump

- Polymer melt pump

- Continuous screen changer

- Underwater pelletizer

- Extrusion die

- Hydraulic screen changer

- Piston melt pump

- Granule dryer

- Double-piston screen changer

- Polymer screen changer

- Extrusion screen changer

- Manual screen changer

- Extrusion head

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.