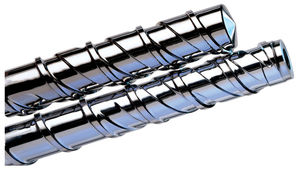

Injection molding screw

Add to favorites

Compare this product

Description

Fusion™ Screw. New barrier screw delivers higher throughput at lower melt temperatures than earlier barrier designs. Has proven its benefits in processing polyolefins, PET, ABS and PLA in various extrusion and blow molding processes. Efficient™ Screw. This barrier screw has proven its value in more than 30 years of field experience. StrataBlend® II Mixer. Low-shear distributive mixer produces a melt of uniform temperature. Its highly suitable for processing shear-sensitive engineering resins such as polycarbonate or ABS as well as polyolefins and materials containing high levels of colorants, fillers or glass fibers. Nano™ Mixer. Breaks up and disperses color and filler agglomerates, including nanoclays. Ideal for processing shear-tolerant materials.

OEM replacements

You can count on Xaloy for precise reproduction of geometry, materials and finish of the original components that came with your machine.

Optimizing performance

Ask us to analyze the performance of your current screw design. Chances are good that we can improve on its output, melt quality and/or melt temperature profile with one of our proprietary high-performance designs or with a screw custom-tailored to your materials and process. And we can prove that it works at our Technology Center in New Castle, Pennsylvania.

Catalogs

No catalogs are available for this product.

See all of Nordson Xaloy‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.