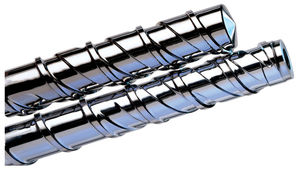

Bimetallic injection molding barrel

Add to favorites

Compare this product

Description

The structural shell of Xaloy bimetallic barrels consists of a microalloy steel that maintains high strength and straightness after casting of the wear-resistant alloy lining. Unlike some barrel manufacturers, Xaloy can produce long barrels up to 240 in. (6.1 m) without resorting to butt welding. The benefit to you is a stronger, straighter barrel with no seams to trap polymers that can degrade and contaminate your process.

Test conditions: The German Plastics Institute, Darmstadt Germany, used standard molding equipment to inject 10 kg of nylon and polycarbonate materials containing 30 and 50% glass fibers through a 0.5 mm ø orifice in test specimens made of the barrel alloys.

Xaloy X-800 and X-102 barrels meet the needs for wear and corrosion resistance for more than 90% of all extrusion requirements.

Catalogs

No catalogs are available for this product.

See all of Nordson Xaloy‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.