Chamber oven JCP 1724 Jet Cleaner™pyrolysiselectricvacuum

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- pyrolysis

- Heat source

- electric

- Atmosphere

- vacuum

- Other characteristics

- for the plastics industry

Description

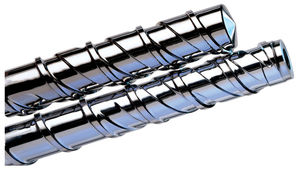

The Model JCP 1724 Jet Cleaner with working dimensions of 15 1/2 and 23 1/2 depth represents one of the most popular model sizes of the Xaloy Jet Cleaner product line.

It is ideally suited for small to intermediate size cleaning applications. All Xaloy Jet Cleaners utilize heat and vacuum to remove material such as thermoplastic from metal parts. In most cases cleaning cycles are accomplished within 120-240 minutes at an operating temperature range between 800°F and 900°F and a vacuum of twenty-five (25) inches of mercury. The unit can be easily installed in any area having available facilities of water supply, water drain and electrical power.

Operation

Cleaning is totally automatic.

The operator loads the parts into the parts tray, moves the carriage assembly to the operating position, secures the door, sets the cycle time and temperature, starts the unit and walks away. The parts to be cleaned are heated in an oxygen starved chamber where the polymer melts and drains into the primary trap collector pan. Remaining polymer is vaporized and then water scrubbed in a secondary trap where condensates are collected in a secondary trap basket. At the end of the cycle the chamber is automatically depressurized and the heaters and vacuum pump shut down. The operator then simply opens the chamber door, removes the cleaned parts, checks and cleans the traps if necessary and the unit is ready for another cycle.

Catalogs

JCP 1724 Jet Cleaner

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.