- Materials - Tools - Components

- Semi-finished products

- North Refractories Company

- Products

- Catalogs

- News & Trends

- Exhibitions

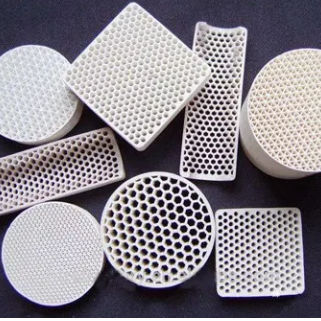

Ceramic honeycomb distributionforging

Add to favorites

Compare this product

Characteristics

- Material

- ceramic

- Domain

- distribution, forging

Description

Honeycomb ceramic with more characteristics such as high surface area, high heat transfer ability, strong thermal shock resistance, high operating temperature, anti-iron oxide skin erosion, effective in reducing the size...

What is HTAC System

High Temperature Air Combustion System is a revolutionary combustion system, which achieves the outstanding fuel saving by high preheated air combustion and high efficiency waste heat recovery.

Honeycomb ceramic with more characteristics such as high surface area, high heat transfer ability, strong thermal shock resistance, high operating temperature, anti-iron oxide skin erosion, effective in reducing the size and weight of regenerative boxes. It can achieve low NOx emission more than 40%.

What Advantages HTAC system has

Lower NO2 by avoiding very high peak-temperatures

CO2 reduction, Fuel consumption decreases,

CO2 emissions decreases

Energy saving

Thermal energy from exhaust gases used to heat up combustion air

Higher heat flux from flames.

Equipment size reduction

Uniform heat flux distribution and thermal field uniformity

Volume of the combustion chamber is fully used

3.Honeycomb Ceramic Regenerator

Honeycomb Ceramic Regenerator is the main components of High Temperature Air Combustion Technology. It has been widely used in various heating furnaces such as pusher-type heating furnace, walking-beam heating furnace, heat treatment furnace, forging furnace, melting furnace, firing furnace and ladle heaters, soaking pit, radiant tube burner, lifting furnace, blast furnace hot blast stove etc.

Other North Refractories Company products

Calcium Silicate Insulation

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.