- Metrology - Laboratory

- Metrology and Test Equipment

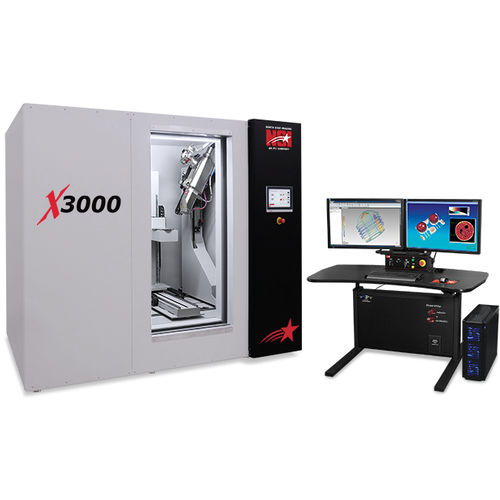

- X-ray inspection machine

- North Star Imaging

- Products

- Catalogs

- News & Trends

- Exhibitions

X-ray inspection machine X3000computed tomography

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, computed tomography

Description

North Star Imaging applications specialists will help you select the best combination of X-ray source and X-ray detector for your application. Whether you need to penetrate through several inches of thick aluminum castings or focus on a gold bond wire the thickness of a human hair, we can configure the X3000 to work for your needs.

SYSTEM CAPABILITIES

Geometric Magnification: >2000x

Overall Maximum System Resolution: <500 nm

CT SOFTWARE

Comprehensive acquisition, processing and archival program with user-friendly interface

High performance image processing and measurement functions

Non-proprietary multiple image format output/input. DICONDE compliant

Automated program functions for fast analysis

Multiple window interface for display of raw image, processed image, density data, etc.

Computed Tomography acquisition module

Optional 3D Computed Tomography calibration, reconstruction and visualization

Optional 4D Computed Tomography

Available with vorteX, subpiX, and mosaiX

X-RAY SOURCE

Voltage Range: 10 kV to 225kV

Minimum Focal Spot Size: <500 nm

X-ray Tube Types: Nano-focus, Micro-focus, Mini-focus

X-RAY DETECTOR

Our applications specialists will recommend the best combination of signal to noise ratio, contrast sensitivity, and efficiency.

Digital X-ray Detector Types: Flat Panel (DDA)

Grade Options: Standard 14 bit, Premium 16bit

Detector Size: 40 cm x 40 cm [16 in x 16 in]

VIDEO

Catalogs

X3000 - Dynamic & Precise

2 Pages

NSI Systems & Services Brochure

20 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.