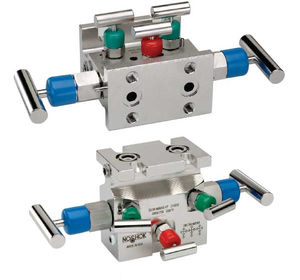

2-channel manifold 2 seriesstainless steel

Add to favorites

Compare this product

Characteristics

- Number of channels

- 2-channel

- Material

- stainless steel

- Operating pressure

Min.: 0 psi

Max.: 10,000 psi

- Port size

0.5 in

Description

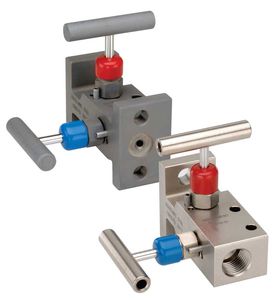

Combines isolating and venting in a single valve, eliminating the need for tubing and fittings

Block valve isolates the downstream process fluids and the bleed valve exhausts upstream fluids enabling static pressure transmitters, switches or gauges to be removed without disturbing the permanent piping installation

Block valve is located on the left side and the bleed valve is located on top in a 90° orientation, venting is to the right

100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliability

2000 Series hard seat valves have 10,000 psi pressure rating @ 200 °F

2100 Series soft seat valves have 6,000 psi pressure rating @ 200 °F

2100 Series valve also features a replaceable Delrin® seat, and straight through porting for bidirectional, high capacity flow and easy roddable cleaning

Blow-out proof stem provides a secondary stem seal in the full open position

FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Graphite packing optional

All stems are 316 Stainless Steel

Stem and bonnet threads are rolled for strength and ease of operation

One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

Slotted spring pin to prevent accidental loosening

Vinyl dust caps for bonnets and stems (non-packing)

Zinc-nickel plated high tensile strength 4140 Steel mounting bolts included for flanged connections

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.