- Products

- Catalogs

- News & Trends

- Exhibitions

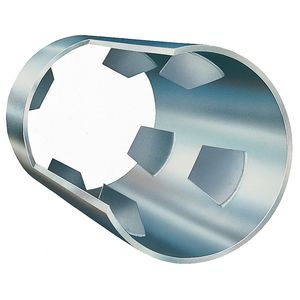

Static mixer KMcontinuousfor liquidshelical

Add to favorites

Compare this product

Characteristics

- Technology

- static

- Batch/continuous

- continuous

- Product type

- for liquids

- Other characteristics

- helical

Description

Kenics static mixers maximize mixing efficiency without the wasted energy and material blockage typically found in more restrictive motionless mixers.

Numerous independent studies have shown that In all Kenics™ KM Series static mixers, a patented helical mixing element directs the flow of material radially toward the pipe walls and back to the center. Additional velocity reversal and flow division results from combining alternating right- and left-hand elements, thus increasing mixing efficiency. All material is continuously and completely mixed, eliminating radial gradients in temperature, velocity, and material composition.

Mixing applications

Turbulent blending

The KM static mixer produces rapid mixing by inducing circular patterns that reverse direction at each element intersection.

Laminar blending

The alternating helical elements of the KM static mixer continually divide, stretch, and reorient the flow stream to produce complete mixing with minimum pressure drop.

Liquid/liquid dispersion

The uniform turbulent shear field of the KM static mixer quickly disperses immiscible liquids and produces a narrow drop size distribution.

Gas liquid dispersion

Gases can be incorporated into turbulent liquids using the KM static mixer. Mass transfer rates are dramatically enhanced to maximize absorption or reaction.

Extrusion

A special line of KM style mixers, called Thermogenizers, are available to blend thermal gradients as well as supplemental color and additive blending.

VIDEO

Catalogs

KM Mixers

2 Pages

Static Mixing Technology

12 Pages

Related Searches

- NOV pump

- NOV industrial pump

- NOV electric pump

- NOV stationary pump

- NOV water pump

- Centrifugal pump

- Self-priming pump

- NOV chemical pump

- NOV stainless steel pump

- NOV dynamic mixer

- NOV suction pump

- Lubricant pump

- NOV transfer pump

- NOV pump for the chemical industry

- NOV compact pump

- Lubricating oil pump

- NOV batch mixer

- NOV mill

- NOV food product pump

- Metering pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.