- Products

- Catalogs

- News & Trends

- Exhibitions

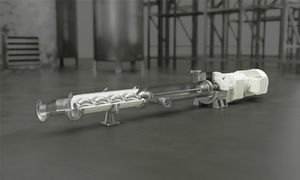

Chemical pump for food productselectricprogressing cavity

Add to favorites

Compare this product

Characteristics

- Fluid

- for chemicals, for food products

- Operation

- electric

- Technology

- progressing cavity

- Mobility

- stationary

- Domain

- for the chemical industry, for the food and beverage industry

- Applications

- transfer, handling, process, feed, recovery, chopper

- Material

- stainless steel

- Other characteristics

- compact, large

Description

Moyno has created a food products processor that combines solids reduction and transfer pumping into one efficient unit. The patented Chopper Hopper™ is a unique and aggressive solids reduction pumping system that reduces whole produce - papayas, pineapples, pumpkins or any other fruits or vegetables - into an easy to handle puree or mash.

The Chopper Hopper™ provides fast, simple and effective handling of waste by-products. Up to three stages of solids reduction are available for coarse, medium and fine particle size.

Features

• Pump and grinding operation in a single, compact package

• Maximizes processing

• Large surge capacity hopper

• Easy disassembly of cutter shafts and pump internals

• Requires minimal maintenance

• Reduces overall cost of ownership

• High flow rates

• Fast process times through three stages of solids reduction

Performance Features

• Rugged progressing cavity pump with proprietary gear joint design

• Multiple Cutter Designs

• Additional cutters located in the extension tube for further solids reduction

• Angled cutters for tearing/grabbing action

• Optional feed into colloid mill for homogenizing

• Carbon or stainless steel construction available

Typical Applications

• Food processing

• Waste handling for disposal

• Rework or recovery of product

• Rendering plants

• Slaughter plants - process internal organs

• Ethanol production

• Orange peels, juicers

• Waste potatoes

Catalogs

No catalogs are available for this product.

See all of NOV Inc.‘s catalogsRelated Searches

- NOV pump

- NOV industrial pump

- NOV electric pump

- NOV stationary pump

- NOV water pump

- Centrifugal pump

- Self-priming pump

- NOV chemical pump

- NOV stainless steel pump

- Lubricant pump

- NOV transfer pump

- NOV pump for the chemical industry

- NOV suction pump

- NOV compact pump

- Lubricating oil pump

- Submersible pump

- Mechanically-actuated pump

- NOV food product pump

- NOV discharge pump

- Standard pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.