- Products

- Catalogs

- News & Trends

- Exhibitions

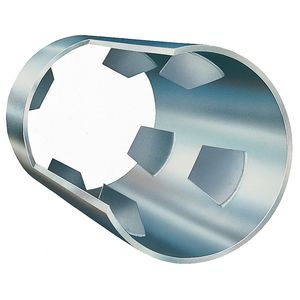

Static mixer KMX-V seriescontinuousfor liquidspolymer

Add to favorites

Compare this product

Characteristics

- Technology

- static

- Batch/continuous

- continuous

- Product type

- for liquids

- Applications

- polymer

Description

The KMX-V static mixer is the best choice for demanding mixing applications, such a those involving fluids with extreme viscosity or volume ratios.

PRINCIPLES OF OPERATION

The KMX-V utilizes cross-stream mixing and flow splitting to achieve very rapid blending. Each element is approximately one pipe diameter in length and consists of multiple intersecting blades, which generate fluid layers as the mixture flows downstream. Each blade features concave construction offering better cross-stream flow than flat blades for superior mixing per unit length in tough, high viscosity ratio applications. Sheets of low viscosity additives are driven along the trough of each blade and abruptly sheared by strong cross-stream velocity gradients as they pass around the upstream surface.

LAMINAR BLENDING

As the additive enters the mixer, it is driven along the trough of each blade. At each blade intersection, the additive is sheared by strong cross-stream velocity gradients as it passes around the upstream surface. This mixing mechanism occurs thousands of times within a short mixing length. The result is that the additive is sheared into continuously finer striations and distributed evenly through the pipe and into viscous main fluid.

HEAD-TO-HEAD COMPARISON

Lab tests have proven that the concave surfaces of the KMX-V element promote more cross-stream flow than competitive designs with flat blades. This feature enhances the performance of the mixer in tough high viscosity ratio applications. Sheets of low viscosity additives are driven along the trough of each blade and abruptly sheared by strong cross-stream velocity gradients as they pass around the upstream surface.

Catalogs

No catalogs are available for this product.

See all of NOV Inc.‘s catalogsRelated Searches

- NOV pump

- NOV industrial pump

- NOV electric pump

- NOV stationary pump

- NOV water pump

- Centrifugal pump

- Self-priming pump

- NOV chemical pump

- NOV stainless steel pump

- NOV dynamic mixer

- Lubricant pump

- NOV transfer pump

- NOV pump for the chemical industry

- NOV suction pump

- NOV compact pump

- Lubricating oil pump

- NOV batch mixer

- NOV mill

- NOV food product pump

- Metering pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.