- Production Machines

- Cutting Machine

- Plasma cutting machine

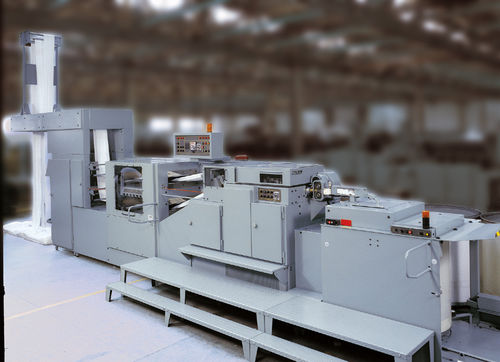

- NSC FIBRE TO YARN

Plasma cutting machine TT12for metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- plasma

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Cutting speed

Min.: 0 mm/min

(0 in/s)Max.: 40,000 mm/min

(26.247 in/s)

Description

The mastery of the chemical filaments crush cutting converting

Sliver perfect evenness and cleanlinessParfaite régularité et propreté du ruban

Tow checking with metal detectors and tension limiters,

Systems of flaments separation and relaxation before cutting

Wide range of cutting diagrams adaptable to the final product requirement,

Precise cutting at high speed

High technology GC drafting head

Delivery speed up to 400 m/min

Technical specifications *

UseCrush cutting converting of chemical filaments tows of 50 to 120ktex presented in boxes or in bales

Filament fineness1.3 to 17dtex

AlimentationCreel with tow spreading-out system

Input loadMaxi. 240ktex

Delivery1 can Ø 1,000mm, height 1,200mm single end

Automatic doffing with square motions

Filament separating setSteel cylinder Ø 100mm

Rubber cylinder Ø 130mm

Pneumatic pressure at 4 bars: 17daN/cm

Feeding setTwin cylinders Ø 100/100mm

Coated cylinder Ø 130mm

Pneumatic pressure at 4bars: 12.5 daN/cm

Cutting deviceSteel anvil cylinder Ø 193mm

Cutting roller Ø mini 156mm, maxi 168mm

Pneumatic pressure: from 700daN for 3bars to 920daN for 4.4 bars

Cutting roller pitch75, 88 or 105mm

Hauteur diagram variationCV (H) up to 35%

Catalogs

Converter TT12

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.