- Production Machines

- Forming Machine

- Stamping unit

- NSM MAGNETTECHNIK GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

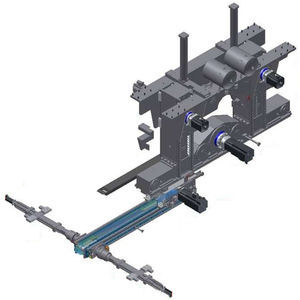

Stamping unit

Add to favorites

Compare this product

Description

Hot forming enables the production of body parts which meet the highest safety and quality standards with simultaneous reduction of the component weight. The procedure requires an automation process that can be reproduced at any time. NSM realizes the entire automation chain: from blank feeding to the furnace, via press loading and parts removal ,up to the fully automatic stacking of the finished parts in transport racks or containers.

• Maximum production capacity due to optimal cycle times

• Scalable line layouts in accordance with customer requirements

• Integration of the various furnace and press systems

• Fully automatic line / tool change

• Press loading and parts removal with robots or high-speed feeders

• Interfaces to quality assurance and the collection of production data

Catalogs

No catalogs are available for this product.

See all of NSM MAGNETTECHNIK GmbH‘s catalogsOther NSM MAGNETTECHNIK GmbH products

Press Automation Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.