- Packing - Handling - Logistics

- Conveying

- Lifting conveyor

- NSM MAGNETTECHNIK GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

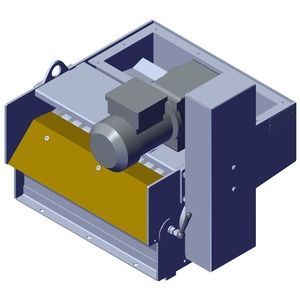

Lifting conveyor STF 81 seriestransferfeedingparts

Add to favorites

Compare this product

Characteristics

- Function

- lifting, transfer, feeding

- Transported product

- parts, for small parts, workpiece

- Applications

- for heavy loads, for heavy-duty applications

- Maximum load

25 kg

(55.116 lb)

Description

NSM heavy-duty step conveyors are available in various designs, with different step widths and thicknesses available depending on the task.

Step conveyors combine the greatest possible part-protection of the workpieces to be supplied with a good pre-orientation of the individual parts on the conveyor steps. NSM provides a wide range of standard models for a wide variety of use cases. From the simple lifting conveyor with a downstream extraction conveyor for small parts (for example, in front of assembly lines), up to the heavy-load conveyor for workpiece weights up to 25 kg, as used in the feeding of induction heating plants or forming presses.

The movable lifting steps of the conveyor convey the workpieces out of the hopper. The sinusoidal movement characteristic ensures a gentle transfer of the workpieces from the upper lifter stage to the subsequent conveying or sorting device. If a linear swing section is used, the workpieces are guided over sorting baffles.

Double and incorrect layers are reversed in the feed hopper, respectively the separate forehopper. Correct layers are made available individually standing in partial stagnation or without stagnation pressure in a separation compartment for removal handling.

Catalogs

No catalogs are available for this product.

See all of NSM MAGNETTECHNIK GmbH‘s catalogsRelated Searches

- NSM MAGNETTECHNIK conveyor

- NSM MAGNETTECHNIK belt conveyor

- NSM MAGNETTECHNIK transport conveyor

- Horizontal conveyor

- Conveyor for the food industry

- Feeder

- Sorting machine

- Inclined conveyor

- Drag chain conveyor

- Handling conveyor

- Modular conveyor

- Automated feeder

- Feeder conveyor

- Transfer conveyor

- Unloading conveyor

- Vertical conveyor

- Mobile conveyor

- Conveyor system

- Heavy load conveyor

- NSM MAGNETTECHNIK parts conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.