- Packing - Handling - Logistics

- Conveying

- Feeder conveyor

- NSM MAGNETTECHNIK GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

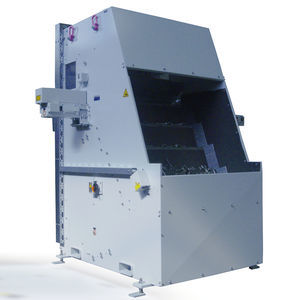

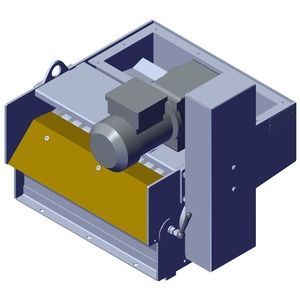

Feeding conveyor for pipe

Add to favorites

Compare this product

Characteristics

- Function

- feeding

- Transported product

- for pipe

Description

Bars and pipe material with dimensions in the range 400 – 2,000 mm cannot generally be handled by bulk material feeding systems. Workpieces with these dimensions require manual placement in the correct position in a storage and singling system.

Positioned next to one another, the pipes are pulled from the feed hopper, whereby they are either received individually by tappet strips or in chain pockets and removed from the hopper. Depending on the customer requirement, behind the deflection, the pipes either roll into a supply V-block or an alignment station, in which e.g. an optional weld seam detection can be integrated.

The NSM pipe feeding systems are available with a pusher system with a lateral stop or with the inside walls of the hopper adjustable on both sides.

Catalogs

No catalogs are available for this product.

See all of NSM MAGNETTECHNIK GmbH‘s catalogsRelated Searches

- NSM MAGNETTECHNIK conveyor

- NSM MAGNETTECHNIK transport conveyor

- NSM MAGNETTECHNIK belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Feeder

- Sorting machine

- Inclined conveyor

- Drag chain conveyor

- Materials handling conveyor

- Modular conveyor

- Automated feeder

- Feeding conveyor

- Transfer rail conveyor

- Discharge conveyor

- Vertical rail conveyor

- Mobile conveyor

- Conveyor system

- Heavy load rail conveyor

- NSM MAGNETTECHNIK parts conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.