- Hydraulics - Pneumatics

- Filter and Separator

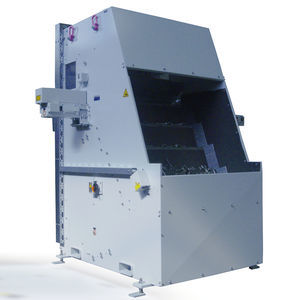

- Magnetic filtration unit

- NSM MAGNETTECHNIK GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Magnetic filtration unit 23 serieswaterautomaticcompact

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic

- Designed for

- water

- Other characteristics

- compact, automatic

- Flow

Min.: 55 l/min

(14.529 us gal/min)Max.: 1,300 l/min

(343.424 us gal/min)- Filtration size

100 mm

(3.937 in)

Description

Permanent magnetic coolant filtering units are used for the automatic filtration and cleaning of Fe particles from contaminated coolants (emulsions, aqueous solutions as well as cutting and grinding oils) which are produced on processing machines.

The coolant to be cleaned must flow smoothly (laminar) over the entire width of the receiving water, since in this way a high filter efficiency is achieved. The coolant passes through the magnetic roller in the radial direction. The Fe particles and the particles adhering to the ferromagnetic parts are attracted to the rotating roller and discharged. The adjustable scraper plate is slanted against the roller and allows the entrained liquid to run back, while the particles are removed from the roller and fall into the reservoir. Our compact, space-saving plants guarantee an extremely long service life with virtually no maintenance.

Catalogs

Datasheet

5 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.