- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

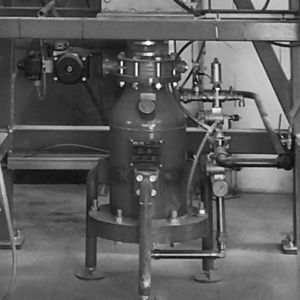

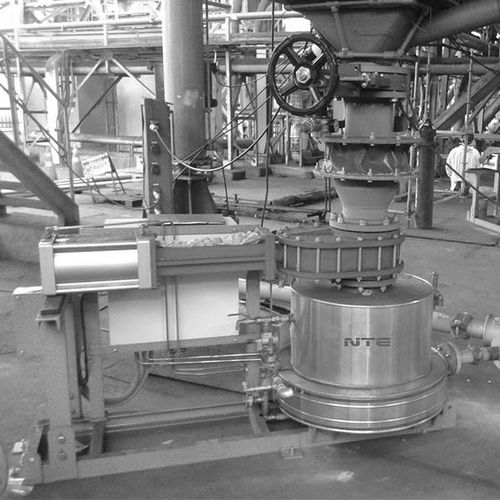

Dense phase pneumatic conveying system Minijet Ash on Skid M504fuel oilfor biomassfly ash

Add to favorites

Compare this product

Characteristics

- Type

- dense phase

- Product applications

- fly ash, fuel oil, coal powder, for biomass

Description

The Minijet Ash on Skid is a pre-assembled and pre-wired unit, suited for fly ash dense phase conveying systems. It can be installed under silos and hoppers, bag house and ESP, economizers, pre-heater and cyclones.

The special double ceramic disc valve is suitable for heavy duty industry and high temperatures (up to 400 ° C) with reduced maintenance.

A remote digital control panel is placed on the skid. The system is therefore robust, compact, flexible and cheap.

The reduced air consumption allows the use of Ash On Skid Minijet anywhere, simply by connecting to a network of compressed air.

NTE Process combined the fluidized membrane technology of its Minijet, a compact and robust transporter suitable for potentially cohesive powders, with Air Assist® patented technology, suitable for controlled injection of air along the conveying lines.

This is a winning technology in all fly ash conveying applications, from coal, fuel oil or biomass even for long distances and high flow rates.

Catalogs

No catalogs are available for this product.

See all of NTE Process Srl‘s catalogsRelated Searches

- NTE Process pneumatic conveying system

- Big bag station

- Dosing feeder

- Powder pneumatic conveying system

- NTE Process dense phase pneumatic conveying system

- Powder dosing feeder

- Big bag emptying station

- Volumetric dosing feeder

- Bulk products pneumatic conveying system

- Food product dosing feeder

- Vacuum pneumatic conveying system

- Granulate dosing feeder

- High-precision dosing feeder

- Food pneumatic conveying system

- Granulate pneumatic conveying system

- Bulk material pneumatic conveying system

- Pneumatic conveying system for the pharmaceutical industry

- Abrasive product pneumatic conveying system

- Pneumatic conveying system for the food industry

- Powder pneumatic conveying system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.