- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

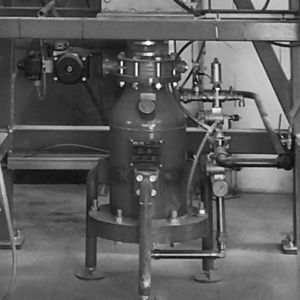

Vacuum pneumatic conveying system NOL-VAC M394dense phasepowderfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- dense phase

- Product applications

- powder, for the food industry, for the pharmaceutical industry, vacuum, food, for dairy products, for chemical products, coffee, sanitary, gas

Description

The new generation of Nol-Vac represents the NTE PROCESS response to the need for vacuum dense phase conveying of low capacity and short distances. Its application is usually suggested for low capacity and distances not higher than 50 m.

Nol-Vac is a pneumatic conveyor able to convey up to 3500 l/h.

This machine is available in different versions and models:

• Basic version: suitable for chemical and food industries

• Sanitary version: suitable for pharmaceutical and dairy industry (DAIRY and GMP)

• Light duty version: suitable for plastic industry and similar

• ATEX version for powder and gas area

• PLUS version: integrates the Air Assist® system, used for longer distances, in case of conveying line with many bends and with non free flowing products or products that have to be preserved (fragile or mixed).

Accessories:

• Multi-Venturi pneumatic pumps;

• Filters with specific characteristics according to the applications;

• Customized piping, joints, vacuum lances for each application;

• Double control system: electro-pneumatic and with PLC.

Advantages:

• In comparison to other pneumatic conveyors on the current market, Nol-Vac has been designed on the basis of the “three pieces” concept: one body, one top with a pneumatic pump, and one controlling discharge valve with filter.

• In pharmaceutical and food industry, the problem concerning product accumulation is solved by the Nol-Tec Europe conveyor, avoiding a common contamination source.

• Nol-Vac reduces the ordinary and extraordinary maintenance time.

Catalogs

No catalogs are available for this product.

See all of NTE Process Srl‘s catalogsRelated Searches

- NTE Process pneumatic conveying system

- Big bag station

- Dosing feeder

- Powder pneumatic conveying system

- NTE Process dense phase pneumatic conveying system

- Powder dosing feeder

- Big bag emptying station

- Volumetric dosing feeder

- Bulk products pneumatic conveying system

- Food product dosing feeder

- Granulate dosing feeder

- High-precision dosing feeder

- Food pneumatic conveying system

- Vacuum pneumatic conveying system

- Bulk material pneumatic conveying system

- Granulate pneumatic conveying system

- Pneumatic conveying system for the pharmaceutical industry

- Abrasive product pneumatic conveying system

- Pneumatic conveying system for the food industry

- Powder pneumatic conveying system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.