- Metrology - Laboratory

- Laboratory Equipment

- Batch mixer

- NTE Process Srl

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

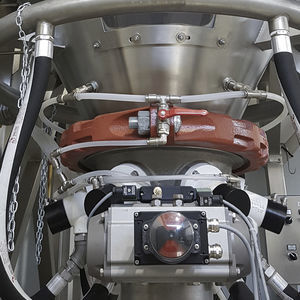

Batch mixer JETMIXER® M531powderverticalhigh precision

Add to favorites

Compare this product

Characteristics

- Batch/continuous

- batch

- Product type

- powder

- Configuration

- vertical

- Other characteristics

- high precision

- Applications

- for the mining industry, for the food industry, for the chemical industry, for the pharmaceutical industry, for the cosmetics industry, laboratory, for the plastics industry, for the petroleum industry, for the glass industry, for the rubber industry, for silos

- Engine power

0 kW

(0 hp)- Capacity

200 l

(52.83 gal)

Description

The NTE Process Jetmixer® M531 is specially designed to homogeneously blend small batches of powder products up to 200 liters. It uses compressed air or other gas pulses to gently move the product, continuously upward and downward until the mixing target is achieved.

The patented design allows to automatically and continuously adjust different parameters in order to actively control the mixing. Furthermore, it leads to a better system performance in terms of mixing time, homogeneity and energy consumption.

The NTE Process Jetmixer® M531 is designed as a standard for food and pharma applications.

Benefits:

quick release sanitary design

simplified and low maintenance

no mechanical moving parts in contact with the product

active mixing parameters control

smooth internal design

The ultimate stand alone Process Solution for labs and small productions

The NTE Process Jetmixer® Unit M537 is designed to homogeneously blend dry materials with different bulk densities and particle sizes in hoppers from 20 l to 5 m³.

It is a a 5 in 1 system for mixing raw material, vacuum conveying, liquid injection, cooling (or degassing) and powder conditioning through a single stand alone process equipment.

Benefits:

• easy-clean

• no mechanical parts in contact with the product

• no contamination derived from friction with traditional ribbons and screw feeders.

MIXING AND POWDER CONDITIONING:

The NTE Process Jetmixer® Unit M537 is particularly suitable for product conditioning (drying, cooling, etc.) with the possibility to inject liquids (perfumes and colors).

Catalogs

Air Mixing - Jetmixer M531

2 Pages

Related Searches

- Batch homogenizer

- Grinding mill

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Agitator for the chemical industry

- Food lump breaker

- Powder blender

- Agitator for the pharmaceutical industry

- Impact grinding mill

- Homogenizer for the cosmetics industry

- Laboratory homogenizer

- Hammer grinding mill

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- Laboratory grinding mill

- Blender for the plastics industry

- Recycling grinding mill

- Dry milling grinding mill

- Ultrafine grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.