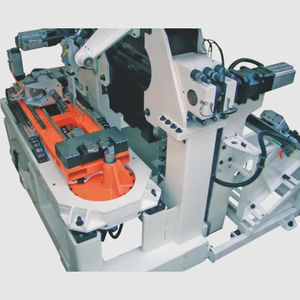

Electric bending machine Robomac 2 for wiresCNC3D

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Product handled

- for wires

- Control

- CNC

- Other characteristics

- 3D

- Bending capacity

Max.: 12 mm

(0.47 in)Min.: 2 mm

(0.08 in)

Description

Double bending head machine allowing multiple options for loading and feeding raw material. Pits retractable orientation clamp allows very small straight distance between the final 2 bends.

Main features

Wire

3D bending from precut lengths or coil

Speed and higher quality for production of long and symmetrical parts

Retractable central clamp allows to achieve extreme short distances (from 3″) between the 2 central bends

Strong 3 position auxiliary clamp fitted on the heads (for guiding and transfer)

Optional – Bending tool cetral axis rotation from model R2106 upwards. Revolving or biplane wire straightener as per request

Modular machine allowing to evolve according to need

Looping capability at both ends

Optional independantly operating bending heads

Man / Machine Interface

Industrial-Grade PC powered by proprietary software

Multilingual dialog and programming interface on a 19″ touch screen

Simulation program

Additional I/O

Internet connection : remote assistance and chat room

Auto-corrective feedback from 3D-measuring devices

Tool editor allows programming of complex parts

Simulation tool to facilitate part set-up

Program execution in slow motion

Catalogs

No catalogs are available for this product.

See all of NUMALLIANCE‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.