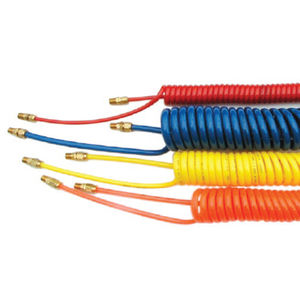

Air hose thermoplasticpolyurethanepolyester

Add to favorites

Compare this product

Characteristics

- Use

- for air

- Material

- thermoplastic, polyurethane, polyester

- Other characteristics

- flexible, lightweight

- Temperature

Max.: 74 °C

(165.2 °F)Min.: -40 °C

(-40 °F)

Description

Lead-In Hoses, also called Pigtails, Whip Ends or Whip Hoses, are used on the working end of self-storing air hose, as well as straight hoses, as a means of minimizing costs by:

Extending the life of the hose - Most hose wear and failure occurs near the point of use, where all of the bending and flexing occurs. A Lead-In Hose will take the brunt of the abuse, giving the hose a much longer service life.

Protecting the coupler - High vibration and impact tools will damage the valve of a coupler, causing premature failure. A short Lead-In Hose ("snubber") between the coupler and air tool will absorb the shock and vibration, protecting the coupler from these damaging effects.

Making the worker more productive - Most air supply hoses are heavy or bulky and difficult to work with. A lightweight, flexible Lead-In Hose makes it easier for the worker to manipulate the air tool, reducing fatigue while increasing productivity

Our Lead-In Hoses are made exclusively from 3/8" Ultra-Lite Superbraid®, combining lightweight, flexibility, durability and a working pressure (200 psi) that meets the requirements of almost every application. The contemporary looking state-of-the-art strain relief sleeve on the tool end protects the hose at its weakest point (at the barb) while enhancing the appearance of the entire assembly. Other manufacturers use a strain relief that limits the ability of the hose to bend, but ours was uniquely designed to take advantage of Polyurethane's flexibility, giving the user a much wider range of motion without the possibility of kinking . . . making it ideal for a Lead-In Hose! Available in a variety of hose lengths in four (4) configurations

Catalogs

Nycoil Catalog 4640

223 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.