- Products

- Tube nylon 6

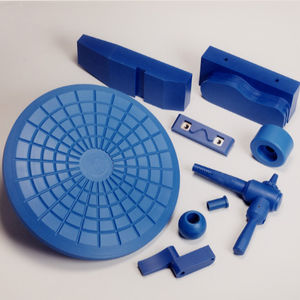

- NYLACAST

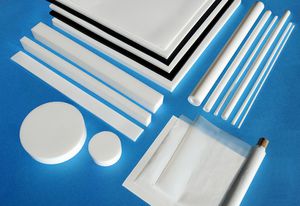

Plate nylon 6 Nylacast PA 6 Naturalrodtube

Add to favorites

Compare this product

Characteristics

- Shape

- plate, rod, tube

Description

Cast Nylons are a range of polyamides produced by a

casting process involving the anionic polymerisation of

caprolactam. This process allows the production of semifinished plate, rod, tube and custom castings that are

largely free of internal stresses. Nylacast PA 6 Natural (also

available in black) is the basic PA 6 grade from which all

the other grades of cast nylon stem. Generally accepted

as the primary engineering polymer, natural cast nylon is

suitable for virtually any plain bearing application, not to

mention a huge range of other applications for which this

versatile grade finds a use. By varying the conditions of

polymerisation the mechanical properties of cast nylon may

be altered to suit specific applications and the performance

of the basic polymer can be enhanced with the addition

of various additives, fillers, lubricants and colourants (see

further grades).

Compared with injection moulding and extrusion grades

of polyamide, cast nylons stand out with their improved

mechanical, thermal and chemical resistance properties.

BENEFITS OF NYLACAST PA 6 NATURAL

• Good mechanical, thermal and chemical resistance

properties

• Universally acknowledged as the primary engineering

polymer

• Good PV and load bearing capabilities

• Improved characteristics over extruded polyamides

• Good wear and abrasion resistance

• Good dimensional stability, largely free from internal

stresses

• FDA Compliance

• Available in a wide range of sizes and colours

INDUSTRY USERS

• Petrochemical

• Aerospace

• Railways

• Ship building

• Food and drink packaging

• Bottling and canning

• Pharmaceuticals

• Steel mills

• Quarrying/mining

• Cranes

• Shoe manufacturing

• Conveyors

Catalogs

NYLACAST PA 6 NATURAL

1 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.