- Products

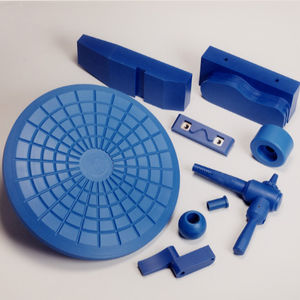

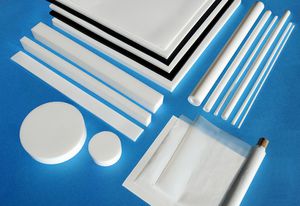

- Plate polyamide

- NYLACAST

Rod polyamide Nylacast Nylubeplatetube

Add to favorites

Compare this product

Characteristics

- Shape

- rod, plate, tube

Description

Nylube was introduced into the Nylacast product range

in 1989 as a logical progression to Oilon with already

outstanding performance as a bearing material. Since

that time, it has proved to be Nylacast’s supreme

wear resisting grade and one of the most important

developments from Nylacast in new materials. Nylube

contains a combined liquid/solid lubricant system which

allows for a coefficient of friction as low as 0.08. This

is below that of almost any other polymer available at

present.

Nylube has substantially improved the wear resistance

abilities compared to that of any other currently available

lubricated grade of cast nylon, whilst retaining excellent

physical property characteristics. The material is

particularly suited to dry running bearing applications

throughout a wide load, speed and temperature range (up

to 120ºC).

Like Oilon, Nylube is suitable for use in applications in the

food and pharmaceutical industries.

BENEFITS OF NYLACAST NYLUBE

• Outstanding wear and abrasion resistance

• Significantly improved PV characteristics

• Improved operating temperature capability

• Outstanding lubrication and low coefficient of friction

• Greatly improved stick/slip capabilities

• Wide load, speed and temperature operating range

• Consistent wear performance throughout product life

• Excellent dimensional stability

• Reduced water absorption

• Excellent chemical resistance

• Blended solid/liquid lubricant system

• FDA compliant for direct food contact applications

INDUSTRY USERS

• Construction

• Aerospace

• Transport

• Ship building

• Food and drink packaging

• Pharmaceuticals

• Steel mills

• Quarrying and mining

• Cranes

• Agriculture

• Recycling and waste management

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.