Plate nylon 6 Nylacast Aquanyl PA 6/12rodtube

Add to favorites

Compare this product

Characteristics

- Shape

- plate, rod, tube

Description

Aquanyl 612 is a copolymer of nylon 6 and nylon 12

produced via the anionic polymerization process using the

monomer’s of caprolactam and Laurinlactam.

Laurinlactam has a similar effect to a plasticizer, but being

a copolymer does not suffer the “Leeching out” problems

of many plasticisers. The aim is to impart a greater degree

of resilience to the material, for which purpose the copolymerisation

method is very successful.

Aquanyl 612 is employed where additional resilience is a

specific requirement for the application, for instance in the

ball valve industry where the application of valve seat seals

benefits greatly from this material. In addition due to its

copolymer make up with nylon 12 the product has a Lower

moisture uptake than cast nylon providing the obvious

benefit of improved dimensional stability

BENEFITS OF NYLACAST AQUANYL 612

• Greater degree of material resilience

• Plasticised benefits without the associated problems

• Reduced water absorption

• Improved dimensional stability

• Good mechanical, thermal and chemical resistance properties

• Improved impact resistance

• Good PV and Load bearing capabilities

INDUSTRY USERS

• Petrochemical

• Pharmaceuticals

• Offshore

• Steel Mills

• Railways

• Quarrying/mining

• Ship building

• Cranes

• Food and drink packaging

• Shoe manufacturing

• Bottling and canning

• Conveyors

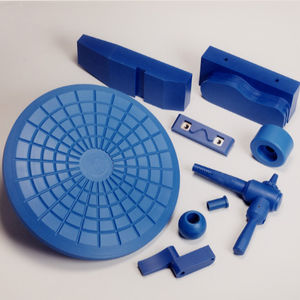

TYPICAL APPLICATIONS

• Seal rings

• Sheaves/Pulleys

• Pipe clamps

• Winches

• Thrust rollers

• Difts

• Nozzles

• Bespoke Components

• Bushes

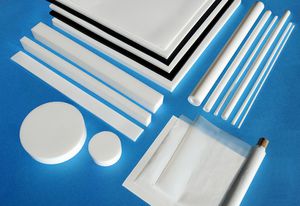

Nylacast Aquanyl 612 is available as standard plate,

rod and thousands of tube OD/ID configurations in

several different Lengths.

Catalogs

No catalogs are available for this product.

See all of NYLACAST‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.