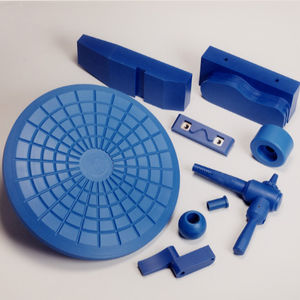

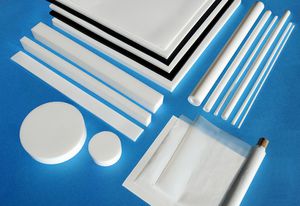

Plate nylon 6 Nylacast Molyrodtube

Add to favorites

Compare this product

Characteristics

- Shape

- plate, rod, tube

Description

Nylacast Moly is a cast nylon material in which improved

crystallisation occurs by the addition of Molybdenum

Disulphide. On account of this the superficial hardness

increases (providing excellent machine ability) and

simultaneously the general mechanical and anti-friction

properties are improved. Due to the fact that the crystal

structure breaks down immediately before the melting

temperature is reached, the thermal properties of the

material are improved over the basic grade.

MoS2 provides a degree of self lubrication leading to

an improvement in the wear properties of the material.

These improved properties, combined with lower

water absorption, extend the range of applications that

Moly has over Natural cast nylon. Dynamic bearing

applications at elevated operating temperatures of up to

105ºC are particularly suited to this material.

BENEFITS OF NYLACAST MOLY

• Increased superficial hardness provides excellent

machine ability

• Improvement in wear properties as a result of dry lubricant

• Improved anti-friction properties

• Improved mechanical properties

• Elevated operating temperatures

• Lower water absorption

• Improved dimensional stability

• Excellent chemical resistance properties

• Good PV and load bearing capabilities

• Extended range of applications

INDUSTRY USERS

• Aerospace

• Cranes

• Railways

• Conveyors

• Ship building

• Offshore

• Food and drink packaging

• Agriculture

• Steel mills

• Waste Management

• Quarrying and mining

• Construction

TYPICAL APPLICATIONS

• Sheaves

• Wear pads

• Rollers

• Bearings

• Spacers

• Bush

• Slide pads

• Chain Wheel

• Chain sheaves

• Hose Clamp

• Wear strips

• Wear plates

• Spacer

• Bespoke Components

Catalogs

NYLACAST MOLY

1 Pages

materials_brochur

20 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.