- Products

- Catalogs

- News & Trends

- Exhibitions

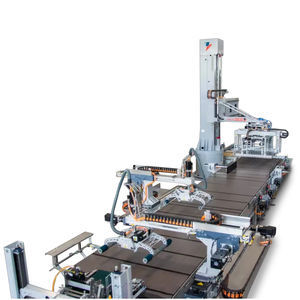

Robotic depalletizer PEGASUSbulk productsfor glass bottlesjerrycan

Add to favorites

Compare this product

Characteristics

- Type

- robotic

- Product applications

- for cans, for glass bottles, jerrycan, bulk products

- Operating mode

- high-speed

- Sector

- bottling industry, for the packaging industry

Description

Robotic solution for dedicated depalletizing operations for bulk containers The robotic solution is extremely flexible allowing to create different configurations with inlets/outlets oriented in any direction. The maximum speed achievable by Pegasus D is 240 layers/hour

HIGH SPEED SOLUTION

POSSIBILITY TO DEPALLETISE TWO CODES SIMULTANEOUSLY

EXTREMELY FLEXIBLE CONFIGURATIONS

BENEFITS

-HIGH-LEVEL EQUIPMENT WITH HIGHEST SAFETY STANDARDS

-TECHNOLOGY THAT ALLOWS MAXIMUM CONTROL OF MOVEMENTS AND FORCES AT PLAY

-PERFECT INSPECTION VISIBILITY DURING NORMAL WORKING CYCLE

-EASY ACCESSIBILITY DURING MAINTENANCE

-COMPACT SOLUTION

compared to traditional solutions needed to depalletize two different codes

-INVERTER-CONTROLLED PALLET CONVEYORS

The Pegasus D allows you to depalletize the pallets by placing layers of bulk product in the production line.

The stripping of the pallet is done on a special platform by the operator that allows the entry into the machine.

The robotized depalletizing head takes the layer from the pallet with the bulk products and deposits it on the belt.

In this phase the single-column device stabilizes the underlying layer that will be picked up later.

The layer positioned on the layer deposited on the belt will be removed by a specific beam device or directly from the head through an optional implementation.

The containers are removed from the storage belt and alligned on single line conveyors.

The machine is completed with the pallet handling conveyors system and any optional accessory device.

Catalogs

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Bottle filler

- Palletizer

- Shrink wrapper

- Semi-automatic filler

- Automatic sleeve wrapping machine

- Automatic palletizer

- Layer palletizer

- Robotic palletizer

- Container filler

- Weight filler

- Shrink wrapper with shrink tunnel

- Cartoner

- Compact filler

- Compact packing machine

- Can filler

- Case palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.