- Products

- Catalogs

- News & Trends

- Exhibitions

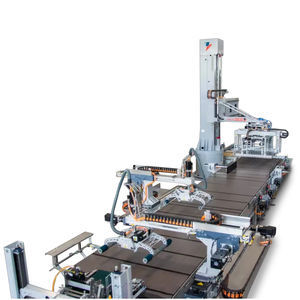

In-line palletizer ORION serieshigh level infeedlow level infeedfor sacks

Add to favorites

Compare this product

Characteristics

- Type

- high level infeed, low level infeed

- Product applications

- for sacks, case, tray, carton

- Sector

- for the packaging industry, bottling industry

- Other characteristics

- automatic, compact, high-speed, online

- Throughput

240 p/h, 300 p/h, 600 p/h

Description

Orion is the traditional in-line palletiser: product infeed and layer formation take place in the same movement direction. This portal palletiser with in-line infeed meets the various customer's requirements A 100% safety solution that combines high performance with great energy saving.

INDUSTRY 4.0 READY

FULLY AUTOMATIC

EXTREMELY COMPACT AND STURDY MACHINE

HIGH SPEED

BENEFITS

•HMI USER FRIENDLY

•WIDE RANGE OF CUSTOMIZATION

•HIGH LEVEL COMPONENTS COMPLYING WITH HIGHEST SAFETY STANDARDS

•UP TO -30% OF ENERGY CONSUMPTION

•MACHINE FULLY OPERATED BY BRUSHLESS MOTORS

•SUITABLE FOR VARIOUS SECTORS

•POSSIBILITY OF PROCESSING VARIOUS TYPES OF PACKS

Designed for medium to high speeds, the product infeed can be from low level (LF-N and Z) or from high level (HM-N), with fixed (LF-N and Z) or mobile pallet (HM-N).

The model Orion Z, derived from the N model, differs from the latter only by the layer pushing system integrated in the machine.

Once the layer has been formed by the Mizar forming unit, the product will be transferred towards the machine and placed onto the pallet, with the possibility to insert flat pads.

The Orion Z model derived from the N model with the only difference of the integrated layer pushing system.

The maximum speed that can be reached by Orion is 600 layers/hour, in the HM-N variant (high level product infeed and moving pallet). Instead, Orion N, with the low level product infeed reaches a maximum speed of 300 layers/hour.

Orion Z model, with low level product infeed and steady pallet, reaches a maximum speed of 240 layers/hour.

All Orion models are integrated with an automatic system forming the layer (Mizar)

VIDEO

Catalogs

No catalogs are available for this product.

See all of OCME‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Liquid filler

- Bottle filler

- Palletizer

- Shrink wrapper

- Semi-automatic filler

- Automatic shrink wrapper

- Automatic palletizer

- Layer palletizer

- Robotic palletizer

- Container filler

- Weight filler

- Shrink wrapper with shrink tunnel

- Cartoner

- Compact filler

- Compact packing machine

- Can filler

- Case palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.