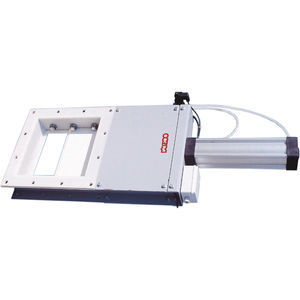

Cleaning booth SFI seriesstainless steelfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- cleaning

- Other characteristics

- stainless steel, for the food industry

Description

The machine is divided into three sections: a central body and two lateral cabins.

Central body in heavy duty welded steel construction with counterweight rotating on double-row roller bearings, incorporates the drive motor.

Each cabin divided in 2, 3 or 4 channels, is constructed of tubular and steel sheets.

The machine is divided into three sections: a centrai body and two lateral cabins housing the

sifting channels. Centrai body in heavy duty welded steel construction with counterweight rotating on double-row roller bearings, incorporates the drive motor.

The machines is suspended by means of fiberglass reeds; access doors to sifting section are also made of fiberglass.

Each sifting channel has a pair of double screw which operate pressure clamping devices for

uniform sieve locking and easy cleaning.

Cabin

Each cabin, divided into two, three or four sifting channels, is made in tubolar sections and welded steel sheets, fastened to the central body by means of high-resistant screws; its internal surfaces are coated with insulating panels to prevent condensation.

Each sifting channel can house up to 30 sieves. The plansister is equipped with standard size sieves with unified section of 750 mm x 750 mm (SFI/L) and 650 mm x 650 mm (SFI/S), consisting of a main frame with stainless steel bottom to collect product and interchangeable sieve cover frame.

Both sieve frames and sieve cover frames are in high quality multilayer wood, internally and

externally lined with laminated formica; in option, plastic polymer food grade certificated, with aluminum alloy frame.

Catalogs

No catalogs are available for this product.

See all of OCRIM‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.