Roundness measuring instrument DIMdiameterinspection

Add to favorites

Compare this product

Characteristics

- Measured value

- roundness, diameter

- Applications

- inspection

Description

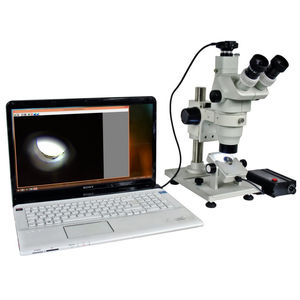

DIM is a measuring and inspection system for wire drawing dies with manual focusing and measuring functions based on image processing. The manual focusing enables a very price competitive setup. Nevertheless the DIM provides a high measuring accuracy by image processing.

Standard measuring functions are:

-inside diameter of drawing dies;

-roundness of inside cylinder of drawing dies.

DIM is a measuring system for diameter and roundness of wire drawing dies.

The measurement is performed optically by image processing software.

Because of the manual focusing the DIM is a very price competitive solution, but provides a high measuring accuracy too!

Additionally, the DIM provides the option of the visual inspection of the drawing die by eyepiece.

The DIM is equipped by default with 3 measuring optics, which covers a diameter measuring range from 0,1mm to 5mm.

The software provides special functions to determine the exact focus position. In connection with the Software, following measuring accuracies can be achieved:

Drawing Die Diameter Measuring accuracy

‹0,4mm ±3 µm

0,4…2,4mm ±5 µm

2,4…5,0mm ±10 µm

The software offers the following functions:

-Live video representation of the camera image on the PC screen

-automatic measurement of diameter and roundness of the drawing die

Catalogs

No catalogs are available for this product.

See all of OEG‘s catalogsRelated Searches

- Measuring device

- Measuring machine

- Automatic test equipment

- Optical measuring machine

- Automatic measuring machine

- Automatic measuring device

- Laboratory measuring device

- Diameter measuring machine

- Laser measurement system

- Geometry measuring device

- Thickness measurement system

- Optical measuring device

- Angle measuring machine

- PC-controllable testing device

- Process measuring device

- Measuring column

- Manual measuring device

- Non-contact measuring device

- Diameter gauge

- Flatness measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.