- Products

- Catalogs

- News & Trends

- Exhibitions

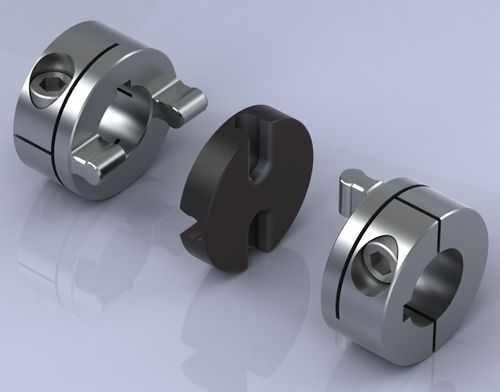

Oldham coupling UI seriesflange

Add to favorites

Compare this product

Characteristics

- Type

- Oldham

- Installation system

- flange

- Torque

Min.: 0.08 Nm

(0.059 ft.lb)Max.: 59 Nm

(43.5162 ft.lb)- Rotational speed

Min.: 4,000 rpm

(25,132.74 rad.min-1)Max.: 6,000 rpm

(37,699.11 rad.min-1)

Description

Advantages:

Protects driven component by serving as a mechanical “fuse” – an inexpensive replaceable plastic midsection shears under excess load

Protects support bearings by exerting consistently low reactive forces, even under large misalignments

Zero backlash and moderate torsional stiffness

Electrical insulation

Accommodates large radial misalignment in a short length

Accommodates much larger angular misalignment then standard Oldham coupling

Easy installation in blind or difficult installations when through-bores are used

Economically priced compared to other couplings with similar performance characteristics

Inexpensive replaceable wear element

Low moment of inertia

Disavantages:

Lower peak torque and torsional stiffness than standard Oldham coupling

Slightly non-homokinetic transmission (that is, the driven and driving shafts don’t move at exactly the same speed throughout one rotation) when angular misalignment is significant

Axial reactive loads exerted on support bearings when torque approaches maximum

Accommodates only a small axial misalignment

Typical Applications:

Types UC and UI are used in light-duty applcations with large angular misalignment, including instrumentation and positioning systems; UA is used in heavy-duty mission-critical high-torque applications requiring a fail-safe coupling, including servo-controlled valves, mining, and crushing equipment.

Catalogs

No catalogs are available for this product.

See all of OEP Couplings‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.