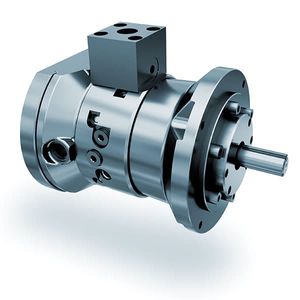

Hydraulic axial piston pump PFBA-6metalsteeltest

Add to favorites

Compare this product

Characteristics

- Type

- axial piston

- Material

- steel, metal

- Applications

- water, test

- Other characteristics

- high-pressure, standard, axial, high-speed

- Pressure

Max.: 700 bar

(10,153 psi)Min.: 501 bar

(7,266 psi)- Flow rate

23.4 l/min

(6.18 us gal/min)- Speed

1,800 rpm, 2,000 rpm

(11,310 rad.min-1, 12,566 rad.min-1)- Weight

45 kg

(99.21 lb)- Power

34.2 kW

(46.5 hp)

Description

The PFBA is a fixed displacement, axial-piston pump. It’s proven itself in a variety of operations—including die casting and injection molding machines, high-pressure test rigs, civil and marine projects, intensifier systems, extrusion presses, forging presses and high-pressure forced lubrication systems for long turbines as well as metal forming machines. And like all Oilgear pumps, it’s designed to handle high water content and low-viscosity fluids.

PRODUCT DETAILS

Originally part of the Towler high-pressure pump line, PFBA pumps are extremely reliable when working with water-based fluids. The PFBA-6 has two high-pressure discharge ports.

This pump line is designed for high-speed operation. It’s also compatible with high-pressure and high-shock loads. That’s because of the swashmember angle. At 13 degrees, it creates a low piston head loading.

Attached to the swashmember, a polymer-coated plate provides a bearing surface for thrust loads. The six hardened steel pistons located in a stationary body are not subject to centrifugal force. This reduces load and wear. An optional, built-in supercharge pump lubricates and provides case flow that cools the main pump and eliminates the need for an external supercharge pump.

STANDARD FEATURES

Six hardened steel pistons located in a stationary body are not subject to centrifugal force, thus reducing load and wear

The piston load is caused by pumping action only, therefore higher operating

speeds are possible

Catalogs

Pump Line

1 Pages

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Compact pump

- Piston pump

- Hydraulic pump

- Hydraulic piston pump

- Line pump

- Axial pump

- OEM pump

- Hydraulic gear pump

- Compact hydraulic pump

- Hand hydraulic pump

- Pump unit

- High-pressure hydraulic pump

- Industrial pump unit

- Hydraulic pump with electric motor

- Stationary pump unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.