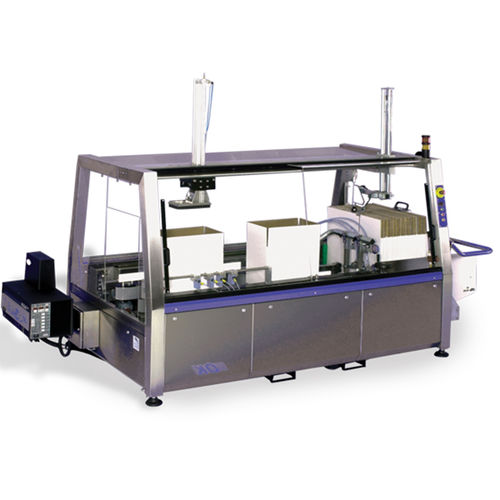

Automatic cardboard box/case erector Superformer HMhot-melt gluehigh-speedfor the food industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Technology

- hot-melt glue

- Other characteristics

- high-speed, for the food industry

- Throughput

Max.: 20 p/min

Min.: 9 p/min

Description

Superformer SF1-HM Hot Melt Glue Case Erector -

Unique features of this machine include stainless steel exterior finish, automatic case squaring system, easy size change, case monitoring and display with fault finding indications.

FEATURES:

Quick and easy size change.Glue and case monitoring.Single frame, in line design.Stainless steel exterior finish.

BENEFITS:

Increased production efficiencyand flexibility.Operator friendly and reliability.Ease of set up, training and operation.Clean and durable finish, preferred in food and other industries. -

TECHNICAL SPECIFICATIONS SUPERFORMER SF1M-HM:

Case range: -

Superformer SF1-HM

8.00” x 8.00” x 6.00” (LxWxH)min.

200mm x 200mm x 150mm (LxWxH)min.

24.00” x 20.00 x 24.00” (LxWxH)max.

600mm x 500mm x 600mm (LxWxH)max.

Superformer SF1M-HM

8.00" x 6.00" x 3.00" (LxWxH)min.

200mm x 150mm x 70mm (LxWxH)min.

18.00" x 14.00" x 16.00" (LxWxH)max.

450mm x 350mm x 400mm (LxWxH)max.

Speed: - Up to 15 cases per minute.

Hot-melt applicator: - Nordson Pro Blue 7 hot melt system.

Case magazine: - Horizontal, belt driven, indexing magazine, length 40”(1000mm).

Electric: - 480V, 3 Phase, 60Hz standard. Other voltages to

requirement. 400V, 3 Ph, 50 Hz.

Compressed air: - Constant 80-100 psi, 0.5 CF per cycle, 1/2" supply, clean, dry and unlubricated air.

Controls: - Allen Bradley PLC. 2 digit alphanumeric display.

Finish; - Stainless steel electrical enclosure and cover sheets.

Machine Handling: - Right to left or left to right to requirement.

VIDEO

Catalogs

No catalogs are available for this product.

See all of OK International‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Food product filling machine

- Filling system for the chemical industry

- Multi-head filler

- Sealer

- Case sealer

- Checkweigher

- Heat sealer

- Adhesive tape case sealer

- Cardboard box/case erector

- Multi-flap case sealer

- Weight filler

- Automatic cardboard box/case erector

- Powder filler

- Filler with conveyor

- Multi-container filler

- Checkweigher with belt conveyor

- Vertical filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.