Parallel electrical cable VEYOR-CABLE™for roboticsfor clean rooms

Add to favorites

Compare this product

Characteristics

- Configuration

- parallel

- Applications

- for robotics, for clean rooms

Description

Many cableveyors are used for the moving parts of conveying robots or small robots. These days, however, the cableveyor method is expensive and also when it is used in a clean room it poses problems such as dust generated from the cableveyor. However, because there are multiple cables, it is currently necessary to use a cableveyor.

Oki Electric Cable Co., Ltd. has developed parallel robot cables in which a number of cables are bonded together, thus eliminating the need for a cableveyor.

Features

It is possible to eliminate the cost of the cableveyor by using a cableveyor-less method.

By not using a cableveyor, it is possible to reduce maintenance costs, and thus greatly reduce the total cost.

The adhesive does not contain organic solvents.

The adhesive used has rubber elasticity, ensuring that the cable has excellent bending performance.

This cable conforms to the RoHS standard.

Applications

Optimum for clean rooms in which a cableveyor cannot be used for the moving parts of robots, and so on, or for moving parts of small equipment, and so on, that is required to be light.

Specifications

For details of possible parallel cable combinations, and so on, please make contact our marketing department.

Construction

Cables that can be arranged in parallel are our cables intended for moving parts.

The O.D. of cables that are arranged in parallel are the same.

The cables are bonded together with two-sided dedicated adhesive.

For other details, please consult with us.

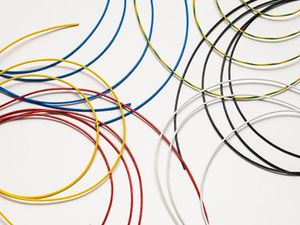

This indicates an example of a parallel robot cable.

Catalogs

No catalogs are available for this product.

See all of Oki Electric Cable‘s catalogsRelated Searches

- Electrical cable

- Copper cable

- Copper electrical cable

- Power cable

- Insulated cable

- Insulated electrical cable

- Data electrical cable

- Flexible cable

- Optical cable

- Flexible electrical cable

- PVC-sheathed cable

- PVC-sheathed electrical cable

- Optical data cable

- Flame-retardant cable

- Halogen-free cable

- Flame-retardant electrical cable

- Halogen-free electrical cable

- Hook-up wire

- Black electrical cable

- Twisted pair cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.