CNC lathe GENOS L3000-Ehorizontal2-axisA2-8

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- horizontal

- Number of axes

- 2-axis

- Spindle mount

- A2-8

- Number of tool stations

- 12 tools

- Performance

- high-precision, powerful, high-productivity, high-speed, high-rigidity

- Other characteristics

- compact, Y-axis

- Associated function

- milling

- Diameter

340 mm

(13.39 in)- Spindle speed

Max.: 3,800 rpm

(23,876.104 rad.min-1)Min.: 38 rpm

(238.761 rad.min-1)- Maximum cutting length

500 mm

(20 in)- Rapids on X

25,000 mm/min, 30,000 mm/min

(16 in/s, 20 in/s)- Rapids on Z

25,000 mm/min, 30,000 mm/min

(16 in/s, 20 in/s)- Nominal power

15 kW

(20.4 hp)

Description

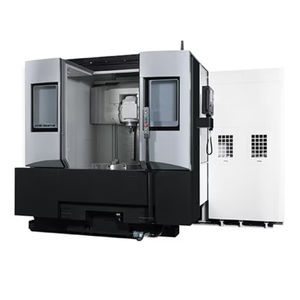

The latest in the GENOS L series of lathes, our GENOS L3000-e features an integral spindle for powerful, high-precision CNC machining. This one-saddle lathe is stronger, smaller, and ideal for cutting a wide range of exotic materials with ease. The integral spindle motor provides increased machining capacity as highly rigid guideways handle powerful cutting capabilities. This highly evolved horizontal lathe delivers turning, optional milling capabilities, optional Y-axis, and optional sub-spindle (W) in a compact footprint.

The GENOS L3000-e (M), with optional milling function has high speed milling and Y-axis options on specific models, allowing users to select the best specifications for a particular workpiece length and shape. Shop floor productivity is increased with a mounted NC tailstock (option) that allows for easy setup of various workpieces. Thermo-Friendly construction—including TAS-C (Thermo Active Stabilizer)—is standard and automatically compensates thermal effects to maintain tight tolerances.

The GENOS L3000-e is an operator-friendly designed machine that simplifies cleaning, filtration, and maintenance tasks. User-friendly features include:

A separate cooling tank for quick servicing

Easy spindle access to reduce operator work burden and maintenance tasks

Reduced chip accumulation during long, continuous runs decreases machine downtime for cleaning

Optional Sub Spindle - for even greater manufacturing flexibility

Spindle - Integral main spindle

OSP suite - A library of apps for stress-free setup and operation

TAS Standard -Thermo Active Stabilizer for improved accuracy & repeatability

Coolant Tank - Separate coolant tank for quick servicing

VIDEO

Catalogs

No catalogs are available for this product.

See all of OKUMA‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

- High-rigidity turning center

- High-performance turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.