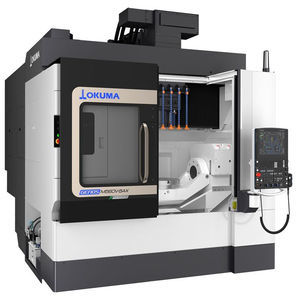

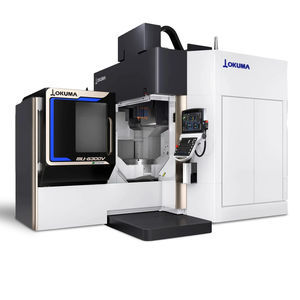

3-axis CNC machining center MILLAC 1052V IIverticalcolumn typecutting

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- column type

- Associated functions

- cutting

- Applications

- heavy-duty

- Other characteristics

- precision, high-rigidity, variable-speed

- X travel

2,050 mm, 3,050 mm

(80.71 in, 120.08 in)- Y travel

850 mm

(33.46 in)- Z travel

750 mm

(29.53 in)- Rotational speed

Max.: 15,000 rpm

(94,248 rad.min-1)Min.: 20 rpm

(126 rad.min-1)- Power

18.5 kW, 22 kW, 26 kW

(25.15 hp, 29.91 hp, 35.35 hp)- Work feed X-axis

12,000 mm/min, 16,000 mm/min

(8 in/s, 10 in/s)- Work feed Y-axis

12,000 mm/min, 16,000 mm/min

(8 in/s, 10 in/s)- Work feed Z-axis

16,000 mm/min

(10 in/s)- Table load capacity

2,500 kg, 3,800 kg

(5,512 lb, 8,378 lb)

Description

Our MILLAC 1052V II vertical machining center is the ultimate in large machining centers with high rigidity, heavy cutting ability, and high operability. The strong base-column construction has optimally placed ribs to counter chatter and twisting during heavy-duty cutting. Traditional box ways are used for all axes to give high accuracy and rigidity over the long term. With the use of variable speed gear head and large-diameter spindle bearings, this machine can perform heavy-duty cutting and rapid machining with large torque from low to high speeds. The ample travel and table designed to withstand heavy loads are well-suited for the machining of large, heavy workpieces.

Catalogs

No catalogs are available for this product.

See all of OKUMA‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- High-rigidity CNC machining center

- 12 tools turning center

- Column type CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- High-performance turning center

- High-rigidity turning center

- Horizontal CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.